Three-phase generators are indispensable for providing reliable and efficient power in electrical engineering. These generators ensure a steady electricity supply for industrial applications, power plants, or large commercial buildings. This article will explore what a three-phase generator is, how it works, its advantages, and various applications. We will also include detailed calculations, tables, and diagrams to illustrate these concepts comprehensively.

Key Points Covered:

- Basics of 3-Phase Generators

- How 3-Phase Generators Work

- Advantages of 3-Phase Generators

- Applications of 3-Phase Generators

- Example Calculations

- Tables and Diagrams

Basics of 3-Phase Generators

A 3-phase generator produces three alternating currents (AC) that are phase-shifted by 120 degrees.

Commonly used in industrial and commercial settings.

More efficient and reliable than single-phase generators.

How 3 Phase Generators Work

Components:

- Rotor: Creates a rotating magnetic field.

- Stator: Contains coils where EMF is induced.

- Prime Mover: Drives the rotor (e.g., internal combustion engine, turbine).

Operation:

When the rotor spins, it creates a rotating magnetic field.

This field cuts through the stator windings, inducing alternating currents.

The three windings are spaced 120 degrees apart, producing three phase-shifted AC outputs.

Advantages of 3-Phase Generators

- Higher efficiency and power density.

- Smoother power delivery with less fluctuation.

- Smaller and lighter for the same power output.

- Cost-effective in the long run.

Applications of 3-Phase Generators

- Industrial Settings: Powering heavy machinery and motors.

- Power Plants: Generating electricity for the grid.

- Commercial Buildings: HVAC systems, elevators, and other infrastructure.

- Renewable Energy Systems: Wind turbines and other renewable sources.

Example Calculations

To calculate the power output of a 3-phase generator, we use the following formula:

Pout=3×VL×IL×cos(ϕ)

Where:PoutVLILcos(ϕ)=Output Power (Watts)=Line Voltage (Volts)=Line Current (Amperes)=Power Factor

Example:

Assume a 3-phase generator with a line voltage of 400V, line current of 50A, and a power factor of 0.8:

Pout=3×400×50×0.8

Pout≈27,712 Watts or 27.7 kW

Power Loss Calculation:

Power loss in the system can be calculated as the difference between the input power and the output power:

Ploss=Pin−Pout

Assume the input mechanical power provided by the prime mover is 30 kW:

Ploss=30,000W−27,712W

Ploss=2,288W

Summary of Measurements:

| Parameter | Value |

|---|

| Input Power | 30,000 W |

| Output Power | 27,712 W |

| Power Loss | 2,288 W |

Tables and Diagrams

Table 1: Comparison of Single-Phase and Three-Phase Generators

| Efficiency | Lower | Higher |

|---|

| Power Delivery | Fluctuates | Smooth and stable |

| Size and Weight | Larger for same power | Smaller and lighter |

| Cost | Cheaper initially | More cost-effective long-term |

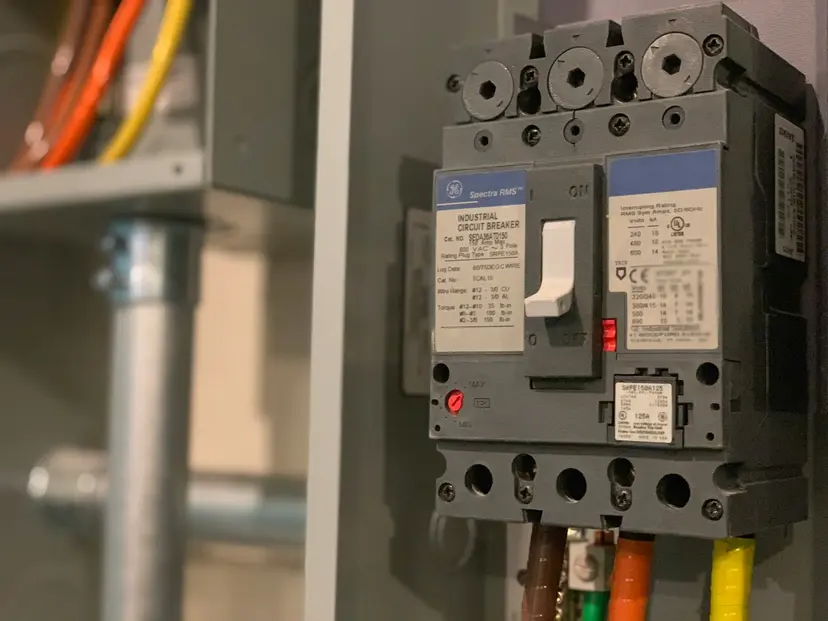

Diagram 1: Schematic of a 3-Phase Generator

Conclusion

Phase generators are fundamental in electrical engineering. They provide efficient and stable power for various applications. Engineers can make informed decisions about their use and maintenance by understanding their operation, advantages, and applications.

If you're interested in learning more about electrical engineering topics or need guidance on selecting the right generator for your needs, explore our other articles or contact us for advice.

Credits