When designing embedded systems and IoT devices, choosing the right communication protocol can make or break your project's success. Two of the most popular serial communication protocols—I2C (Inter-Integrated Circuit) and SPI (Serial Peripheral Interface)—each offer distinct advantages for connecting microcontrollers with sensors, displays, memory devices, and other peripherals.

Understanding when to use I2C vs SPI is crucial for electrical engineers, embedded system designers, and IoT developers who need to optimize their designs for performance, cost, and reliability. This comprehensive guide will help you master both protocols and make informed decisions for your next project.

Whether you're building Arduino-based prototypes, industrial automation systems, or commercial IoT products, the choice between I2C and SPI impacts everything from PCB layout complexity to system performance and debugging capabilities.

Table of Contents

- Protocol Fundamentals

- I2C Communication Protocol

- SPI Communication Protocol

- Detailed Comparison: I2C vs SPI

- Performance Analysis

- Practical Applications

- Implementation Examples

- Troubleshooting Guide

- Best Practices

Protocol Fundamentals

Understanding Serial Communication

Both I2C and SPI are synchronous serial communication protocols, meaning they use a shared clock signal to coordinate data transfer between devices. This approach offers several advantages over asynchronous communication:

- Reliable timing: Clock synchronization eliminates timing errors

- Higher speeds: No start/stop bits required

- Error reduction: Synchronized sampling reduces data corruption

- Efficient bandwidth utilization: More data bits per transmission

Master-Slave Architecture

Both protocols implement a master-slave communication model:

- Master device: Initiates communication, generates clock signals, and controls the bus

- Slave devices: Respond to master requests and follow the master's timing

- Bus arbitration: Protocols handle multiple device access to shared communication lines

I2C Communication Protocol

I2C Protocol Overview

I2C (Inter-Integrated Circuit), developed by Philips (now NXP) in 1982, is a multi-master, multi-slave communication protocol designed for short-distance communication between integrated circuits.

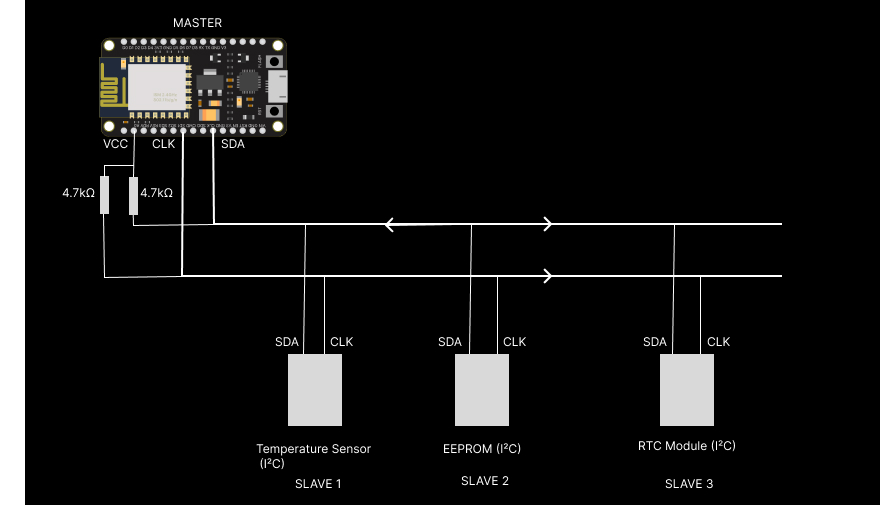

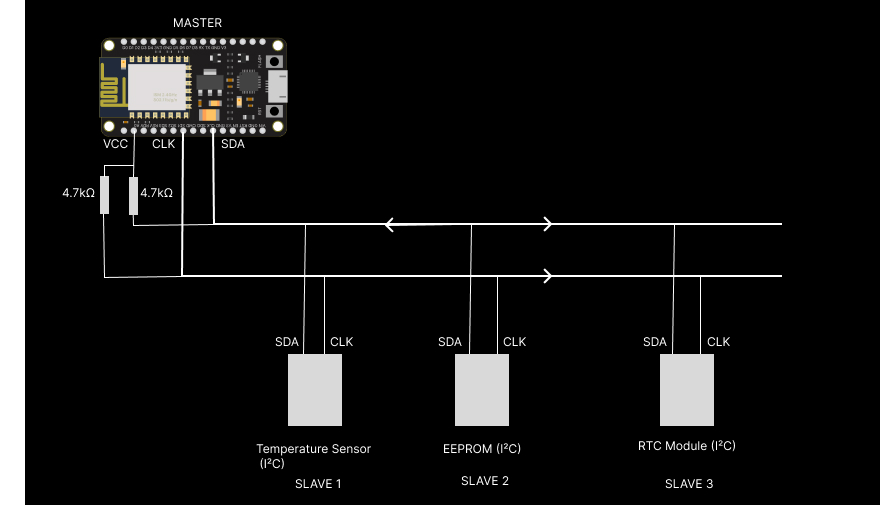

I2C Hardware Requirements

I2C requires only 2 wires for communication:

| Signal | Function | Description |

|---|

| SDA | Serial Data | Bidirectional data line |

| SCL | Serial Clock | Clock signal generated by master |

| Pull-up Resistors | Signal Conditioning | Required on both SDA and SCL lines (typically 4.7kΩ) |

All devices share SDA and SCL lines. Each slave has a unique 7-bit address.

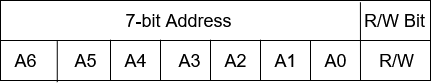

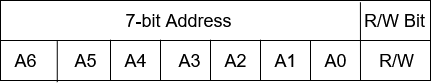

I2C Addressing System

I2C uses a sophisticated addressing system to communicate with multiple devices:

- 7-bit addressing: Standard mode supports 128 unique addresses (0x00-0x7F)

- 10-bit addressing: Extended mode supports 1024 addresses

- Reserved addresses: Several addresses reserved for special functions

- Address collision: Hardware resolves conflicts when multiple masters access the bus

- Bits 7-1: Device address

- Bit 0: Read (1) or Write (0) operation

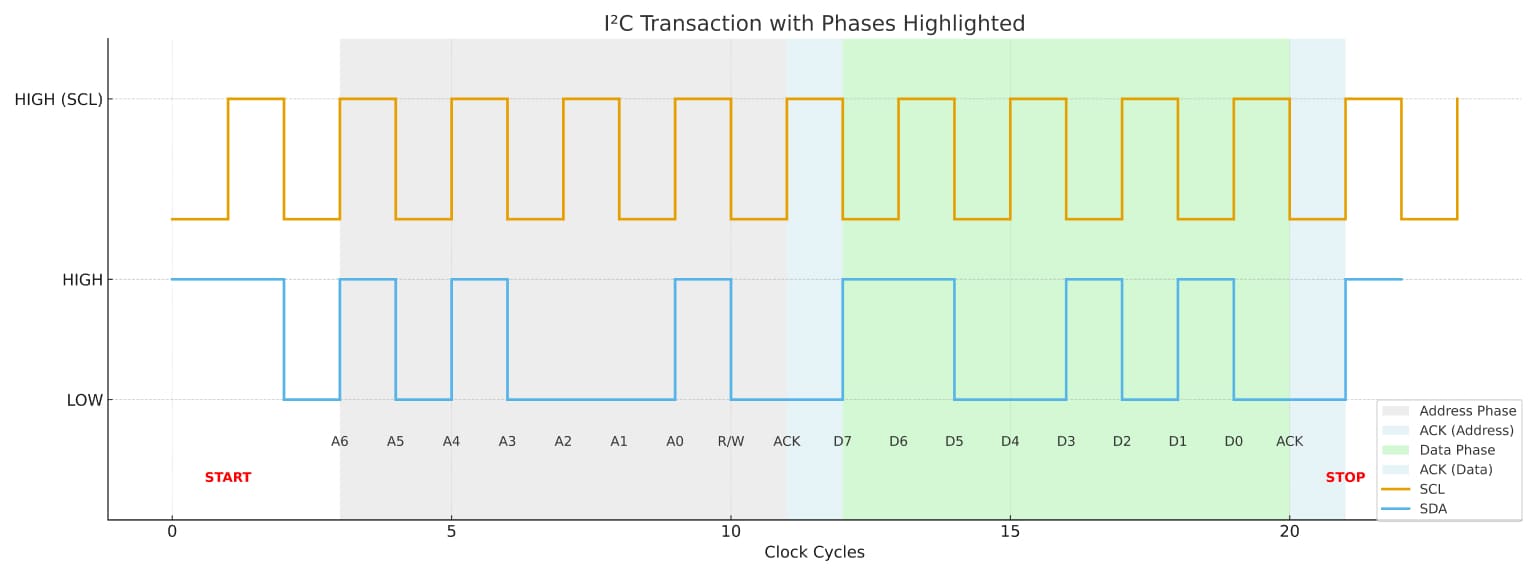

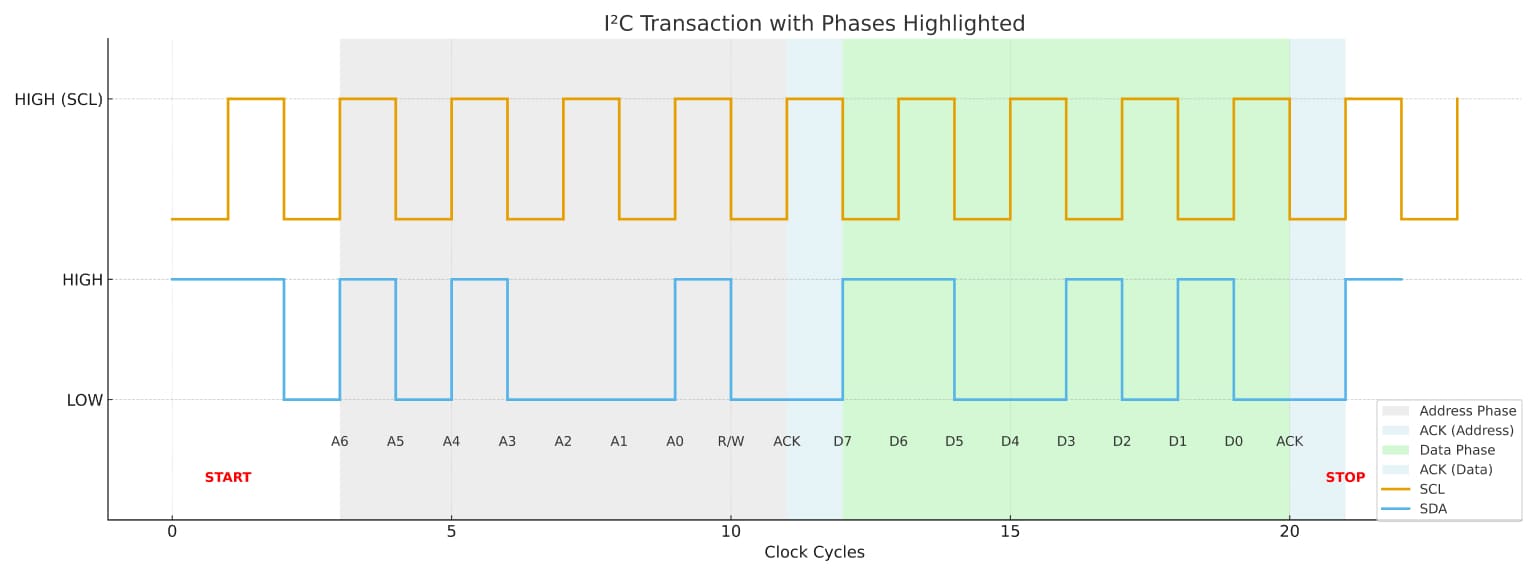

I2C Communication Process

1. Start Condition

- SDA transitions from HIGH to LOW while SCL is HIGH

- Indicates beginning of transmission

2. Address Phase

- Master sends 7-bit slave address + R/W bit

- Addressed slave responds with ACK (acknowledgment)

3. Data Phase

- 8-bit data bytes transmitted

- Each byte followed by ACK/NACK from receiver

4. Stop Condition

- SDA transitions from LOW to HIGH while SCL is HIGH

- Indicates end of transmission

I2C Timing Diagram

I2C communication 7-bit address with read/write bit timing diagram

I2C Speed Modes

| Mode | Maximum Speed | Application |

|---|

| Standard Mode | 100 kbps | Basic sensor communication |

| Fast Mode | 400 kbps | Display interfaces, EEPROMs |

| Fast Mode Plus | 1 Mbps | High-performance sensors |

| High Speed Mode | 3.4 Mbps | Advanced applications |

| Ultra Fast Mode | 5 Mbps | Specialized high-speed devices |

SPI Communication Protocol

SPI Protocol Overview

SPI (Serial Peripheral Interface), developed by Motorola in the 1980s, is a synchronous communication protocol designed for high-speed, short-distance communication between microcontrollers and peripheral devices.

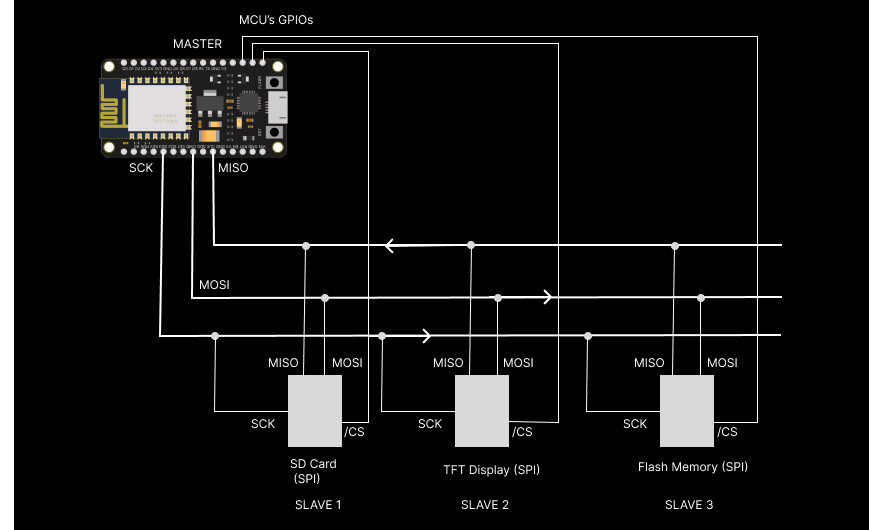

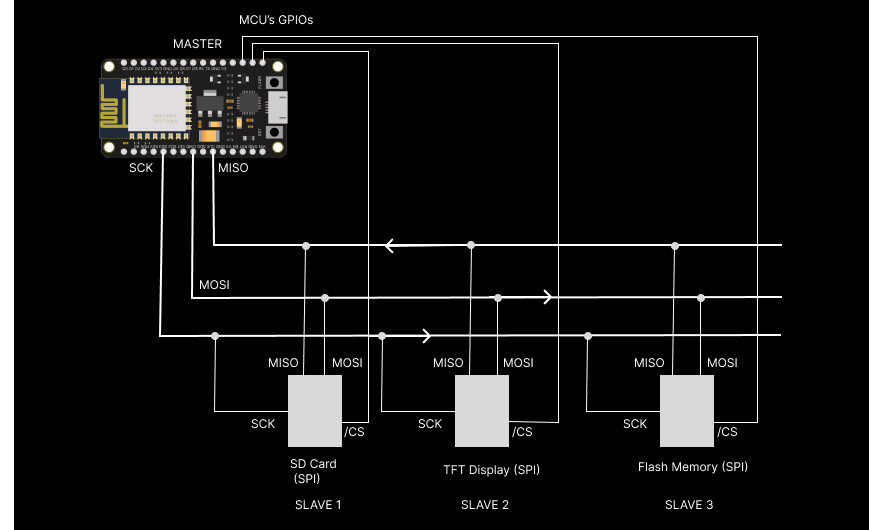

SPI Hardware Requirements

SPI requires 4 wires for basic communication:

| Signal | Alternative Names | Function | Direction |

|---|

| SCLK | SCK, CLK | Serial Clock | Master → All Slaves |

| MOSI | SDO, DI, SI | Master Out, Slave In | Master → Slave |

| MISO | SDI, DO, SO | Master In, Slave Out | Slave → Master |

| SS/CS | NSS, CE | Slave Select/Chip Select | Master → Individual Slave |

SPI Communication Modes

SPI supports four different communication modes based on Clock Polarity (CPOL) and Clock Phase (CPHA):

| Mode | CPOL | CPHA | Clock Polarity | Clock Phase |

|---|

| Mode 0 | 0 | 0 | Idle Low | Sample on Rising Edge |

| Mode 1 | 0 | 1 | Idle Low | Sample on Falling Edge |

| Mode 2 | 1 | 0 | Idle High | Sample on Falling Edge |

| Mode 3 | 1 | 1 | Idle High | Sample on Rising Edge |

SPI Communication Process

1. Slave Selection

- Master pulls specific SS/CS line LOW to select target slave

- Selected slave becomes active and ready for communication

2. Clock Generation

- Master generates SCLK signal at desired frequency

- Clock speed determined by master and must be compatible with slave

3. Data Exchange

- Simultaneous bidirectional data transfer

- MOSI: Master sends data to slave

- MISO: Slave sends data to master

- Data shifts on each clock edge

4. Transaction Complete

- Master pulls SS/CS HIGH to deselect slave

- Slave returns to idle state

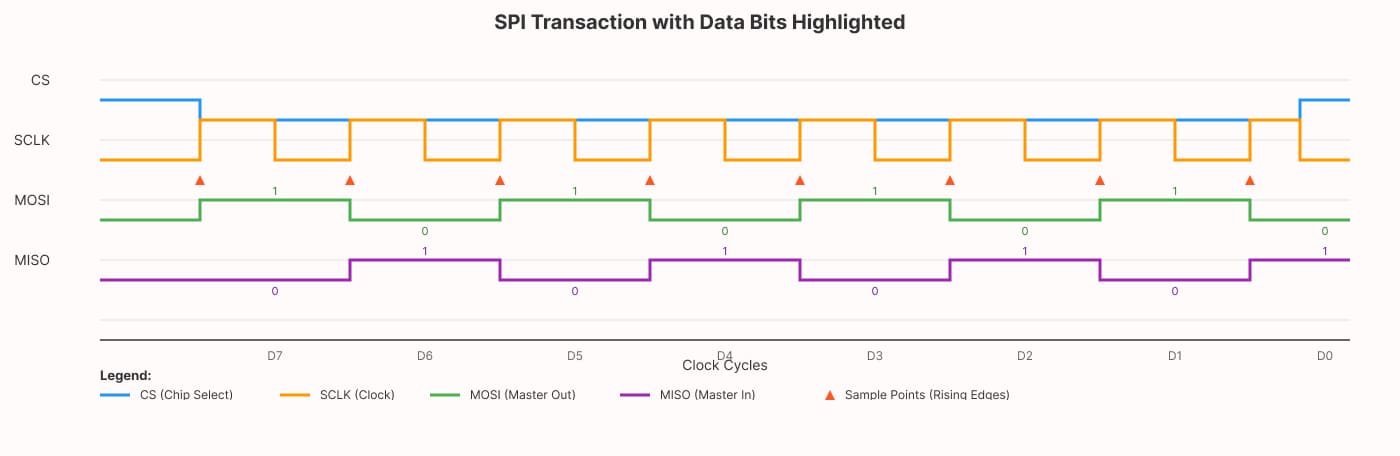

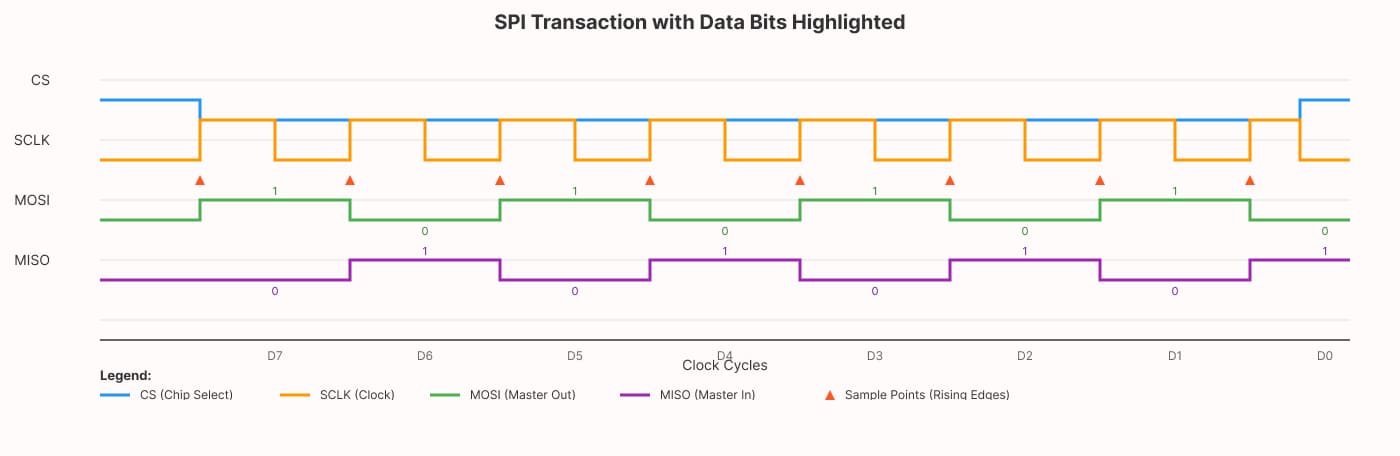

SPI Timing Diagram (Mode 0)

SPI communication full duplex 8-bit data transfer timing diagram

Detailed Comparison: I2C vs SPI

Hardware Complexity

| Aspect | I2C | SPI |

|---|

| Wire Count | 2 wires (+ power/ground) | 4+ wires (+ power/ground) |

| Pin Requirements | 2 pins regardless of device count | 3 + N pins (N = number of slaves) |

| Pull-up Resistors | Required (4.7kΩ typical) | Not required |

| PCB Complexity | Lower trace count, simpler routing | Higher trace count, more complex routing |

| Connector Cost | Lower (fewer pins) | Higher (more pins) |

Communication Characteristics

| Feature | I2C | SPI |

|---|

| Data Direction | Half-duplex (bidirectional on single wire) | Full-duplex (separate MOSI/MISO) |

| Addressing | Built-in 7-bit or 10-bit addressing | Hardware chip select |

| Multi-master | Supported (with arbitration) | Complex (requires additional logic) |

| Protocol Overhead | Higher (address + ACK bits) | Lower (no addressing overhead) |

| Error Detection | ACK/NACK mechanism | No built-in error detection |

| Parameter | I2C | SPI |

|---|

| Maximum Speed | 3.4 Mbps (High Speed Mode) | 50+ Mbps (implementation dependent) |

| Typical Speed | 100-400 kbps | 1-25 Mbps |

| Distance | Up to 2m (standard), 10m+ with repeaters | < 30cm (PCB), few meters with buffers |

| Capacitive Load | 400pF (standard), 50pF (high-speed) | Varies by implementation |

Device Support and Ecosystem

| Aspect | I2C | SPI |

|---|

| Device Availability | Excellent (sensors, displays, memories) | Excellent (flash, SD cards, displays) |

| Microcontroller Support | Universal | Universal |

| Bus Sharing | Multiple devices per bus | One device per chip select |

| Hot Swapping | Not supported | Not supported |

Throughput Comparison

Let's analyze actual data throughput for both protocols:

I2C Throughput Calculation

For I2C communication, consider the protocol overhead:

- Start condition: 1 bit

- Address: 8 bits (7-bit address + R/W)

- ACK: 1 bit

- Data: 8 bits

- ACK: 1 bit

- Stop condition: 1 bit

Total bits per byte: 20 bits

Efficiency: 8/20 = 40%

At 400 kbps Fast Mode:

- Theoretical throughput: 400 kbps × 0.4 = 160 kbps actual data

SPI Throughput Calculation

For SPI communication:

- No addressing overhead

- No start/stop conditions

- Direct 8-bit data transfer

Total bits per byte: 8 bits

Efficiency: 8/8 = 100%

At 1 MHz clock:

- Theoretical throughput: 1 Mbps × 1.0 = 1 Mbps actual data

Latency Analysis

| Protocol | Setup Time | Per-byte Overhead | Best For |

|---|

| I2C | Address + ACK (~20μs @ 400kHz) | High | Multiple small transactions |

| SPI | CS assertion (~1μs) | Low | Large data transfers |

Practical Applications

When to Choose I2C

Ideal Applications:

- Sensor networks: Multiple temperature, pressure, or environmental sensors

- Display interfaces: Small OLED displays, LCD character displays

- Memory devices: EEPROMs, real-time clocks with NVRAM

- Configuration interfaces: Device settings, calibration data

- IoT sensor hubs: Collecting data from multiple sensors

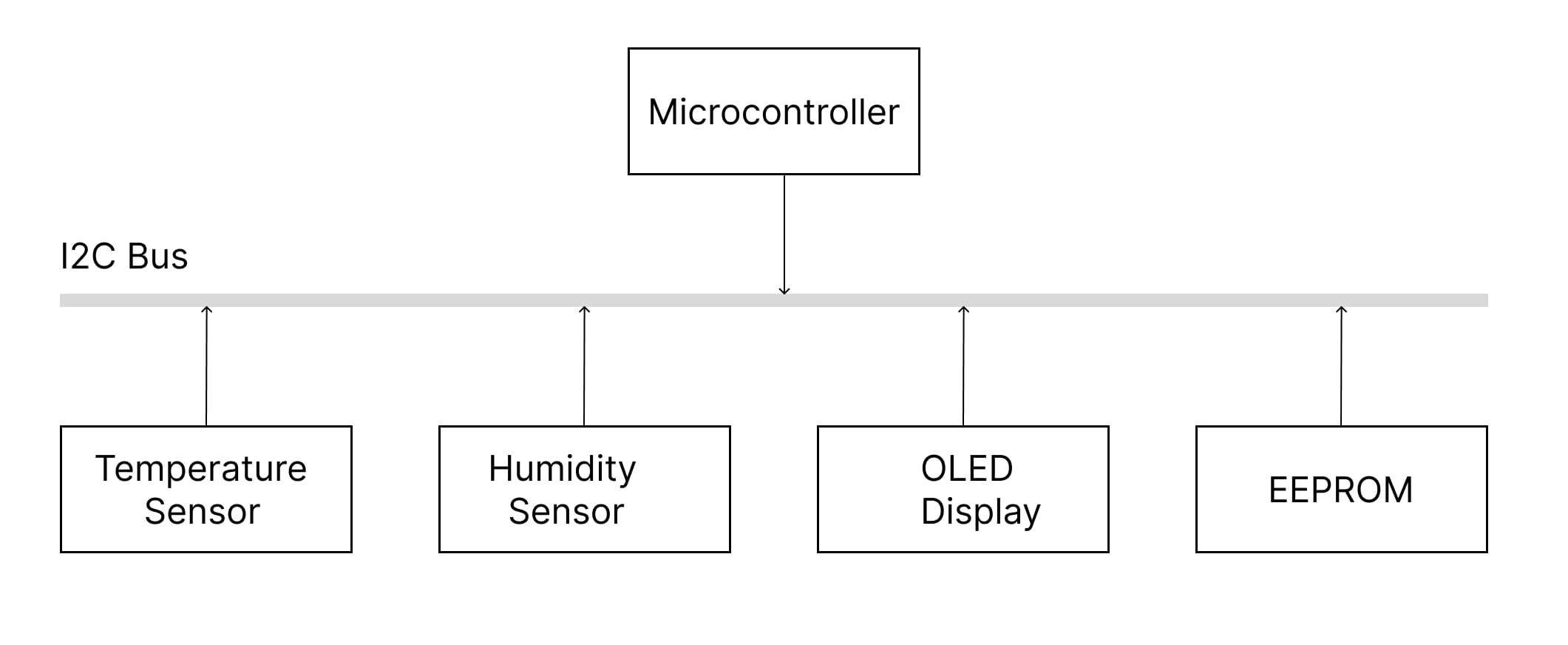

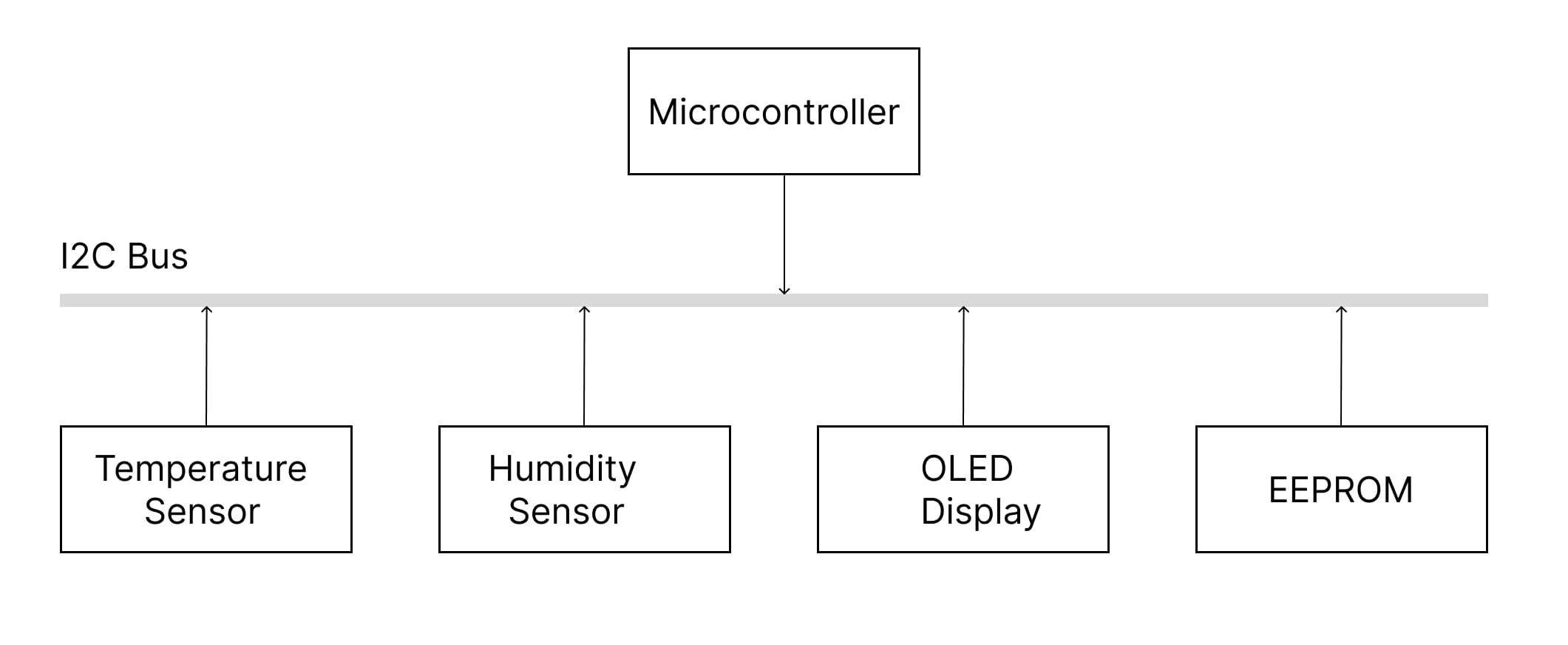

Example I2C System:

Advantages in these applications:

- Minimal pin usage

- Easy to add/remove devices

- Built-in addressing eliminates wiring complexity

- Standard sensor interfaces

When to Choose SPI

Ideal Applications:

- SD card interfaces: File system access, data logging

- Flash memory: External program storage, data storage

- Display controllers: TFT displays, e-ink screens

- ADC/DAC interfaces: High-resolution analog interfaces

- RF modules: Wireless transceivers, GPS modules

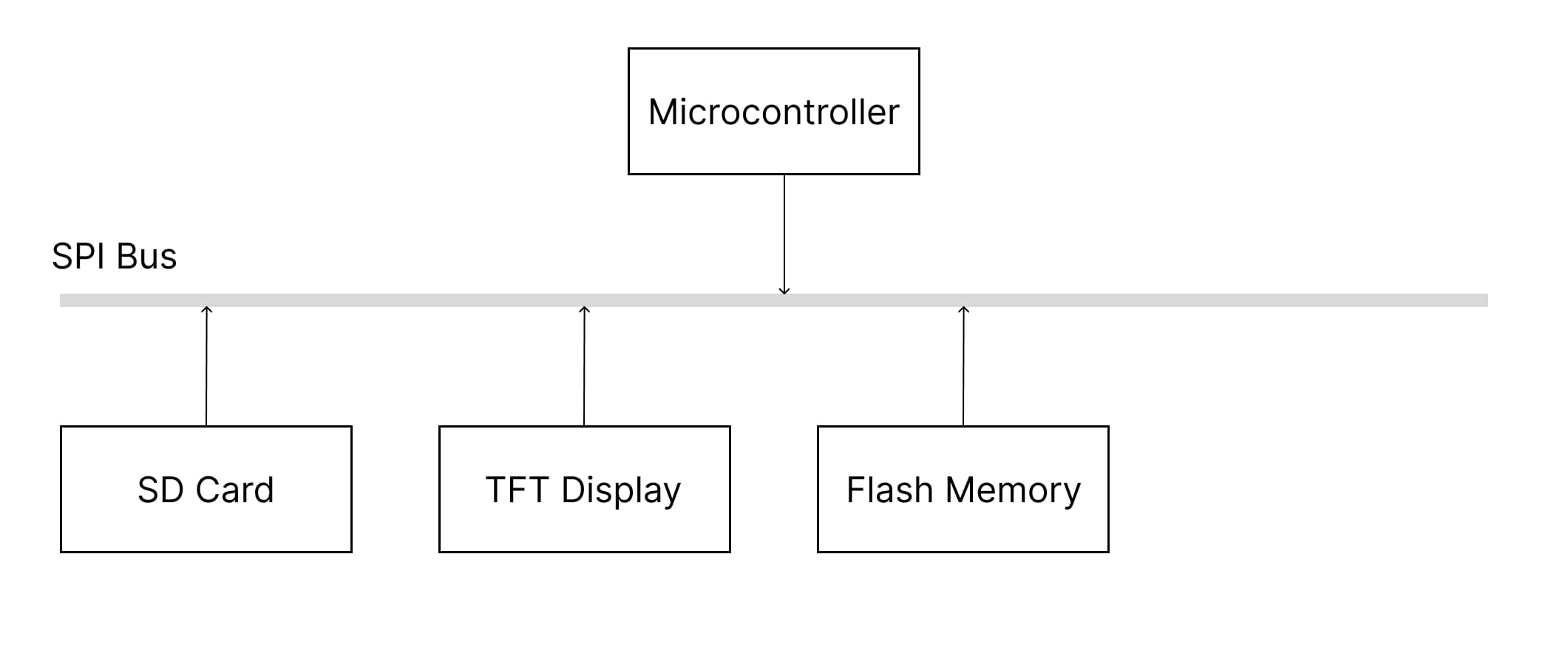

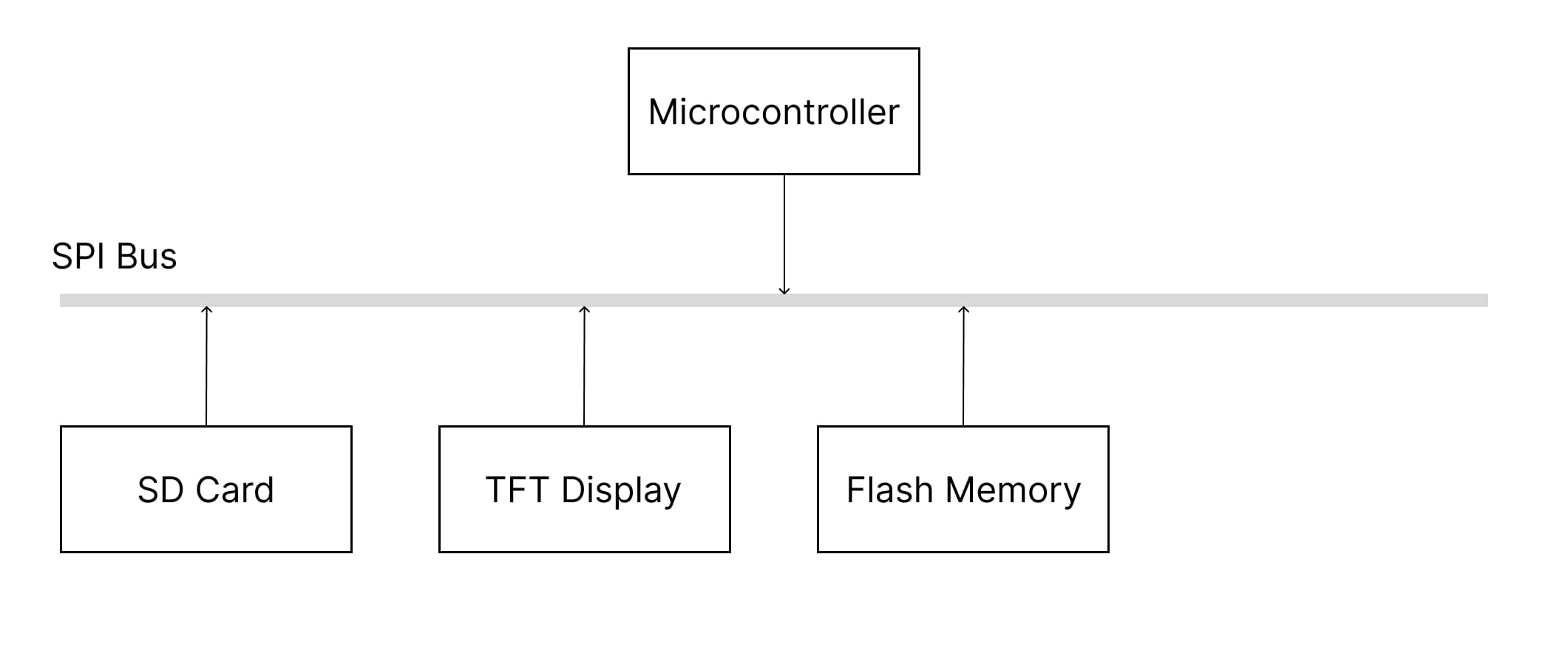

Example SPI System:

Advantages in these applications:

- High-speed data transfer

- Full-duplex communication

- Simple implementation

- Deterministic timing

Industry-Specific Use Cases

Automotive Electronics

| Application | Preferred Protocol | Reason |

|---|

| Sensor Clusters | I2C | Multiple sensors, compact wiring |

| Infotainment Storage | SPI | High-speed SD card access |

| Dashboard Displays | SPI | Fast screen updates |

| Configuration Memory | I2C | Easy addressing, moderate speed |

Industrial Automation

| Application | Preferred Protocol | Reason |

|---|

| Sensor Networks | I2C | Multi-drop capability |

| HMI Displays | SPI | Fast graphics updates |

| Data Logging | SPI | High-speed storage access |

| Device Configuration | I2C | Simple addressing |

Consumer Electronics

| Application | Preferred Protocol | Reason |

|---|

| Smart Home Sensors | I2C | Pin efficiency, multiple devices |

| Camera Modules | SPI | High-speed image data |

| Audio Codecs | I2C | Configuration, SPI for audio data |

| Memory Cards | SPI | Standard interface |

Implementation Examples

Arduino I2C Example

#include <Wire.h>

// I2C Temperature Sensor (LM75A)

#define TEMP_SENSOR_ADDR 0x48

void setup() {

Serial.begin(9600);

Wire.begin(); // Initialize I2C as master

Serial.println("I2C Temperature Sensor Test");

}

void loop() {

float temperature = readTemperature();

Serial.print("Temperature: ");

Serial.print(temperature);

Serial.println(" °C");

delay(1000);

}

float readTemperature() {

// Request 2 bytes from temperature sensor

Wire.requestFrom(TEMP_SENSOR_ADDR, 2);

if (Wire.available() >= 2) {

uint8_t msb = Wire.read();

uint8_t lsb = Wire.read();

// Convert to temperature (LM75A format)

int16_t tempRaw = (msb << 8) | lsb;

tempRaw >>= 5; // Right shift to get 11-bit value

return tempRaw * 0.125; // 0.125°C per LSB

}

return -999; // Error value

}

// Writing to I2C device

void writeToDevice(uint8_t address, uint8_t reg, uint8_t data) {

Wire.beginTransmission(address);

Wire.write(reg); // Register address

Wire.write(data); // Data to write

uint8_t error = Wire.endTransmission();

if (error == 0) {

Serial.println("Write successful");

} else {

Serial.println("Write failed");

}

}

Arduino SPI Example

#include <SPI.h>

// SPI Flash Memory (W25Q32)

#define FLASH_CS_PIN 10

#define CMD_READ_ID 0x9F

#define CMD_READ_DATA 0x03

void setup() {

Serial.begin(9600);

// Initialize SPI

SPI.begin();

pinMode(FLASH_CS_PIN, OUTPUT);

digitalWrite(FLASH_CS_PIN, HIGH); // Deselect initially

// Configure SPI settings

SPI.beginTransaction(SPISettings(1000000, MSBFIRST, SPI_MODE0));

Serial.println("SPI Flash Memory Test");

readFlashID();

}

void loop() {

// Read first 16 bytes from flash

readFlashData(0x000000, 16);

delay(2000);

}

void readFlashID() {

digitalWrite(FLASH_CS_PIN, LOW); // Select device

SPI.transfer(CMD_READ_ID); // Send read ID command

uint8_t manufacturer = SPI.transfer(0x00);

uint8_t deviceType = SPI.transfer(0x00);

uint8_t deviceID = SPI.transfer(0x00);

digitalWrite(FLASH_CS_PIN, HIGH); // Deselect device

Serial.print("Manufacturer ID: 0x");

Serial.println(manufacturer, HEX);

Serial.print("Device Type: 0x");

Serial.println(deviceType, HEX);

Serial.print("Device ID: 0x");

Serial.println(deviceID, HEX);

}

void readFlashData(uint32_t address, uint16_t length) {

digitalWrite(FLASH_CS_PIN, LOW); // Select device

// Send read command and 24-bit address

SPI.transfer(CMD_READ_DATA);

SPI.transfer((address >> 16) & 0xFF);

SPI.transfer((address >> 8) & 0xFF);

SPI.transfer(address & 0xFF);

Serial.print("Data at address 0x");

Serial.print(address, HEX);

Serial.print(": ");

// Read data bytes

for (uint16_t i = 0; i < length; i++) {

uint8_t data = SPI.transfer(0x00);

Serial.print("0x");

if (data < 0x10) Serial.print("0");

Serial.print(data, HEX);

Serial.print(" ");

}

digitalWrite(FLASH_CS_PIN, HIGH); // Deselect device

Serial.println();

}

// SPI configuration for different devices

void configureSPIForDevice(uint8_t mode, uint32_t speed) {

SPI.endTransaction();

SPI.beginTransaction(SPISettings(speed, MSBFIRST, mode));

}

ESP32 Advanced Example

// ESP32 with both I2C and SPI

#include <Wire.h>

#include <SPI.h>

// I2C Configuration

#define I2C_SDA 21

#define I2C_SCL 22

#define I2C_FREQ 400000

// SPI Configuration

#define SPI_MOSI 23

#define SPI_MISO 19

#define SPI_CLK 18

#define SPI_CS 5

void setup() {

Serial.begin(115200);

// Initialize I2C with custom pins

Wire.begin(I2C_SDA, I2C_SCL);

Wire.setClock(I2C_FREQ);

// Initialize SPI with custom pins

SPI.begin(SPI_CLK, SPI_MISO, SPI_MOSI, SPI_CS);

Serial.println("ESP32 Dual Protocol Example Ready");

}

void loop() {

// Use both protocols in same system

scanI2CDevices();

delay(1000);

testSPILoopback();

delay(2000);

}

void scanI2CDevices() {

Serial.println("Scanning I2C bus...");

uint8_t deviceCount = 0;

for (uint8_t addr = 1; addr < 127; addr++) {

Wire.beginTransmission(addr);

uint8_t error = Wire.endTransmission();

if (error == 0) {

Serial.print("Device found at address 0x");

if (addr < 16) Serial.print("0");

Serial.println(addr, HEX);

deviceCount++;

}

}

if (deviceCount == 0) {

Serial.println("No I2C devices found");

}

}

void testSPILoopback() {

// Connect MOSI to MISO for loopback test

digitalWrite(SPI_CS, LOW);

uint8_t testData = 0xAA;

uint8_t received = SPI.transfer(testData);

digitalWrite(SPI_CS, HIGH);

Serial.print("SPI Loopback - Sent: 0x");

Serial.print(testData, HEX);

Serial.print(", Received: 0x");

Serial.println(received, HEX);

}

Troubleshooting Guide

Common I2C Issues

1. No ACK Response

Symptoms: Device not responding, Wire.endTransmission() returns error code

Causes & Solutions:

- Wrong address: Verify device address with datasheet

- Missing pull-ups: Add 4.7kΩ resistors to SDA and SCL

- Power issues: Check device power supply

- Wiring errors: Verify SDA/SCL connections

//Include wire library

#include <Wire.h>

// I2C Configuration

#define I2C_SDA 21

#define I2C_SCL 22

#define I2C_FREQ 400000

void setup() {

Serial.begin(115200);

// Initialize I2C with custom pins

Wire.begin(I2C_SDA, I2C_SCL);

Wire.setClock(I2C_FREQ);

}

void loop() {

scanI2C();

delay(1000);

}

// I2C Device Scanner

void scanI2C() {

for (uint8_t addr = 1; addr < 127; addr++) {

Wire.beginTransmission(addr);

uint8_t error = Wire.endTransmission();

if (error == 0) {

Serial.print("Found device at 0x");

Serial.println(addr, HEX);

}

}

}

2. Bus Lockup

Symptoms: Communication stops working, bus stuck LOW

Solutions:

- Clock stretching timeout: Increase I2C timeout

- Software reset: Reset I2C peripheral

- Bus recovery: Generate clock pulses to free stuck slave

3. Speed Issues

Symptoms: Intermittent communication failures

Solutions:

- Reduce clock speed: Lower from 400kHz to 100kHz

- Check capacitance: Reduce wire length, check pull-up values

- Signal integrity: Use oscilloscope to verify waveforms

Common SPI Issues

1. No Data Transfer

Symptoms: MISO always reads 0x00 or 0xFF

Causes & Solutions:

- Clock mode mismatch: Verify CPOL/CPHA settings

- CS timing: Check chip select assertion/deassertion

- Wiring errors: Verify MOSI/MISO, SCLK connections

- Clock speed: Reduce speed for initial testing

#include <SPI.h>

// SPI Configuration

#define SPI_MOSI 23

#define SPI_MISO 19

#define SPI_CLK 18

#define SPI_CS 5

void setup() {

Serial.begin(115200);

// Initialize SPI with custom pins

SPI.begin(SPI_CLK, SPI_MISO, SPI_MOSI, SPI_CS);

}

void loop() {

testSPIModes();

delay(2000);

}

// SPI Configuration Test

void testSPIModes() {

uint8_t modes[] = {SPI_MODE0, SPI_MODE1, SPI_MODE2, SPI_MODE3};

for (int i = 0; i < 4; i++) {

SPI.beginTransaction(SPISettings(1000000, MSBFIRST, modes[i]));

digitalWrite(CS_PIN, LOW);

uint8_t response = SPI.transfer(0x9F); // Read ID command

digitalWrite(CS_PIN, HIGH);

Serial.print("Mode ");

Serial.print(i);

Serial.print(": 0x");

Serial.println(response, HEX);

SPI.endTransaction();

}

}

2. Data Corruption

Symptoms: Inconsistent data, wrong values

Solutions:

- Clock stability: Use stable clock source

- Signal integrity: Reduce wire length, add ground planes

- CS timing: Ensure proper setup/hold times

- Power decoupling: Add bypass capacitors

3. Multiple Device Issues

Symptoms: Devices interfere with each other

Solutions:

- Individual CS lines: Use separate chip select for each device

- Tri-state outputs: Verify devices properly disconnect MISO

- Bus contention: Check for multiple drivers

- Logic Analyzer: Capture and analyze protocol timing

- Oscilloscope: Verify signal integrity and timing

- Multimeter: Check power supplies and pull-up resistors

- Protocol Decoder: Software analysis of captured signals

Software Debug Techniques

#include <Wire.h>

#include <SPI.h>

// I2C Configuration

#define I2C_SDA 21

#define I2C_SCL 22

#define I2C_FREQ 400000

// SPI Configuration

#define SPI_MOSI 23

#define SPI_MISO 19

#define SPI_CLK 18

#define SPI_CS 5

void setup() {

Serial.begin(115200);

// Initialize I2C with custom pins

Wire.begin(I2C_SDA, I2C_SCL);

Wire.setClock(I2C_FREQ);

// Initialize SPI with custom pins

SPI.begin(SPI_CLK, SPI_MISO, SPI_MOSI, SPI_CS);

}

void loop() {

debugI2C();

delay(1000);

debugSPI();

delay(2000);

}

// I2C Debug Function

void debugI2C(uint8_t address, uint8_t reg) {

Serial.print("Reading from device 0x");

Serial.print(address, HEX);

Serial.print(", register 0x");

Serial.println(reg, HEX);

Wire.beginTransmission(address);

Wire.write(reg);

uint8_t error = Wire.endTransmission();

if (error != 0) {

Serial.print("Transmission error: ");

Serial.println(error);

return;

}

Wire.requestFrom(address, (uint8_t)1);

if (Wire.available()) {

uint8_t data = Wire.read();

Serial.print("Data: 0x");

Serial.println(data, HEX);

} else {

Serial.println("No data available");

}

}

// SPI Debug Function

void debugSPI(uint8_t command) {

Serial.print("SPI Command: 0x");

Serial.println(command, HEX);

digitalWrite(CS_PIN, LOW);

delayMicroseconds(10); // CS setup time

uint8_t response = SPI.transfer(command);

delayMicroseconds(10); // CS hold time

digitalWrite(CS_PIN, HIGH);

Serial.print("Response: 0x");

Serial.println(response, HEX);

}

Best Practices

I2C Best Practices

Hardware Design

- Pull-up resistors: Use 4.7kΩ for standard speeds, 2.2kΩ for higher speeds

- Bus capacitance: Keep total capacitance under 400pF for standard mode

- Power supply: Use clean, stable power with proper decoupling

- EMI protection: Use twisted pairs or shielded cables for longer distances

Software Implementation

- Error handling: Always check Wire.endTransmission() return codes

- Timeout handling: Implement timeouts for communication

- Address validation: Verify device addresses before communication

- Bus recovery: Implement bus recovery mechanisms

// Robust I2C Read Function

bool readI2CDevice(uint8_t address, uint8_t reg, uint8_t* data, uint8_t length) {

// Start transmission

Wire.beginTransmission(address);

Wire.write(reg);

uint8_t error = Wire.endTransmission();

if (error != 0) {

Serial.print("I2C transmission error: ");

Serial.println(error);

return false;

}

// Request data

uint8_t received = Wire.requestFrom(address, length);

if (received != length) {

Serial.println("I2C: Incorrect number of bytes received");

return false;

}

// Read data

for (uint8_t i = 0; i < length; i++) {

if (Wire.available()) {

data[i] = Wire.read();

} else {

Serial.println("I2C: No more data available");

return false;

}

}

return true;

}

// I2C Bus Recovery

void recoverI2CBus() {

pinMode(SDA_PIN, OUTPUT);

pinMode(SCL_PIN, OUTPUT);

// Generate clock pulses to free stuck slave

for (int i = 0; i < 9; i++) {

digitalWrite(SCL_PIN, HIGH);

delayMicroseconds(5);

digitalWrite(SCL_PIN, LOW);

delayMicroseconds(5);

}

// Generate stop condition

digitalWrite(SDA_PIN, LOW);

delayMicroseconds(5);

digitalWrite(SCL_PIN, HIGH);

delayMicroseconds(5);

digitalWrite(SDA_PIN, HIGH);

delayMicroseconds(5);

// Reinitialize I2C

Wire.begin();

}

SPI Best Practices

Hardware Design

- Short traces: Keep SPI traces as short as possible

- Ground planes: Use solid ground planes for signal integrity

- Decoupling: Place bypass capacitors close to ICs

- Clock distribution: Use star topology for clock distribution to multiple slaves

Software Implementation

- CS timing: Ensure proper chip select timing

- Clock configuration: Verify clock polarity and phase

- Speed optimization: Start with low speeds, increase gradually

- Error detection: Implement checksums for critical data

// Robust SPI Transaction Function

bool spiTransaction(uint8_t* txData, uint8_t* rxData, uint16_t length) {

// Configure SPI settings

SPI.beginTransaction(SPISettings(1000000, MSBFIRST, SPI_MODE0));

// Assert chip select

digitalWrite(CS_PIN, LOW);

delayMicroseconds(1); // CS setup time

// Transfer data

for (uint16_t i = 0; i < length; i++) {

rxData[i] = SPI.transfer(txData[i]);

}

// Deassert chip select

delayMicroseconds(1); // CS hold time

digitalWrite(CS_PIN, HIGH);

SPI.endTransaction();

return true;

}

// SPI Device Configuration

struct SPIConfig {

uint32_t clockSpeed;

uint8_t bitOrder;

uint8_t dataMode;

uint8_t csPin;

};

void configureSPIDevice(const SPIConfig& config) {

pinMode(config.csPin, OUTPUT);

digitalWrite(config.csPin, HIGH);

SPI.beginTransaction(SPISettings(

config.clockSpeed,

config.bitOrder,

config.dataMode

));

}

Power Management Considerations

I2C Power Optimization

- Clock stretching: Use to accommodate slow devices

- Dynamic addressing: Disable unused devices

- Low power modes: Put devices in sleep mode when not in use

// I2C Power Management

void setI2CDevicePowerMode(uint8_t address, uint8_t powerReg, bool lowPower) {

Wire.beginTransmission(address);

Wire.write(powerReg);

Wire.write(lowPower ? 0x01 : 0x00);

Wire.endTransmission();

}

SPI Power Optimization

- CS management: Keep devices deselected when not in use

- Clock gating: Disable SPI clock when not needed

- Device sleep: Put SPI devices in sleep mode

Signal Integrity Guidelines

I2C Signal Integrity

- Rise time: Ensure proper rise times (< 1μs for standard mode)

- Bus loading: Calculate total bus capacitance

- Noise immunity: Use proper filtering and shielding

SPI Signal Integrity

- Clock quality: Maintain clean clock signals

- Skew management: Match trace lengths for clock and data

- Termination: Use proper termination for high speeds

Advanced Topics

Multi-Master I2C Systems

I2C supports multiple masters on the same bus through built-in arbitration:

// Multi-master I2C implementation

class I2CMaster {

private:

uint8_t masterID;

bool busAvailable;

public:

I2CMaster(uint8_t id) : masterID(id), busAvailable(true) {}

bool requestBus() {

// Check if bus is available

if (!busAvailable) {

return false;

}

// Attempt to gain bus access

Wire.beginTransmission(0x00); // General call address

uint8_t error = Wire.endTransmission();

if (error == 0) {

busAvailable = false;

return true;

}

return false;

}

void releaseBus() {

busAvailable = true;

}

};

High-Speed SPI Optimization

For maximum SPI performance:

// High-speed SPI with DMA (ESP32 example)

#include "driver/spi_master.h"

spi_device_handle_t spiDevice;

void initHighSpeedSPI() {

spi_bus_config_t busConfig = {

.mosi_io_num = 23,

.miso_io_num = 19,

.sclk_io_num = 18,

.quadwp_io_num = -1,

.quadhd_io_num = -1,

.max_transfer_sz = 4096

};

spi_device_interface_config_t deviceConfig = {

.clock_speed_hz = 10000000, // 10MHz

.mode = 0,

.spics_io_num = 5,

.queue_size = 7

};

spi_bus_initialize(SPI2_HOST, &busConfig, 1);

spi_bus_add_device(SPI2_HOST, &deviceConfig, &spiDevice);

}

void highSpeedTransfer(uint8_t* data, size_t length) {

spi_transaction_t transaction = {

.length = length * 8,

.tx_buffer = data,

.rx_buffer = data

};

spi_device_transmit(spiDevice, &transaction);

}

Protocol Bridging

Sometimes you need to bridge between I2C and SPI:

// I2C to SPI Bridge

class ProtocolBridge {

private:

uint8_t i2cAddress;

uint8_t spiCS;

public:

ProtocolBridge(uint8_t i2cAddr, uint8_t cs)

: i2cAddress(i2cAddr), spiCS(cs) {}

void bridgeCommand(uint8_t command, uint8_t* data, uint8_t length) {

// Receive command via I2C

Wire.onReceive([this](int bytes) {

if (bytes >= 2) {

uint8_t cmd = Wire.read();

uint8_t len = Wire.read();

uint8_t buffer[len];

for (int i = 0; i < len; i++) {

buffer[i] = Wire.read();

}

// Forward to SPI device

forwardToSPI(cmd, buffer, len);

}

});

}

private:

void forwardToSPI(uint8_t command, uint8_t* data, uint8_t length) {

digitalWrite(spiCS, LOW);

SPI.transfer(command);

for (uint8_t i = 0; i < length; i++) {

SPI.transfer(data[i]);

}

digitalWrite(spiCS, HIGH);

}

};

Decision Matrix: Choosing the Right Protocol

Use this decision matrix to select the optimal protocol for your project:

Project Requirements Assessment

| Factor | Weight | I2C Score (1-5) | SPI Score (1-5) | Comments |

|---|

| Pin Efficiency | High | 5 | 2 | I2C uses only 2 pins |

| Speed Requirements | Medium | 2 | 5 | SPI much faster |

| Multiple Devices | High | 5 | 3 | I2C handles addressing automatically |

| Implementation Simplicity | Medium | 3 | 4 | SPI simpler protocol |

| Error Handling | High | 4 | 2 | I2C has built-in ACK/NACK |

| Distance | Low | 4 | 2 | I2C better for longer distances |

Application-Specific Recommendations

IoT Sensor Networks

Recommendation: I2C

- Multiple sensors on same bus

- Pin efficiency crucial

- Moderate speed requirements

- Built-in addressing simplifies wiring

Recommendation: SPI

- High-speed ADCs

- Large data transfers

- Deterministic timing required

- Full-duplex communication beneficial

Mixed-Signal Applications

Recommendation: Both

- I2C for configuration and slow sensors

- SPI for high-speed data and storage

- Optimize each interface for its purpose

Future Developments and Trends

I2C Evolution

I3C (Improved Inter-Integrated Circuit)

- Higher speeds: Up to 12.5 Mbps

- Lower power: Dynamic voltage scaling

- Backward compatibility: Works with existing I2C devices

- In-band interrupts: Eliminates need for separate interrupt lines

I2C Extensions

- SMBus compatibility: Enhanced power management features

- PMBus support: Power management applications

- HDMI CEC: Consumer electronics control

SPI Advancements

Quad SPI (QSPI)

- 4-bit data transfer: MOSI, MISO, WP, HOLD

- Higher throughput: 4x data rate improvement

- Memory applications: Flash memory interfaces

Dual SPI

- 2-bit data transfer: Increased bandwidth

- Cost-effective: Better than QSPI for many applications

Emerging Alternatives

CAN Bus

- Automotive applications: Robust communication

- Differential signaling: Better noise immunity

- Multi-master: Built-in arbitration

USB-C and USB4

- High-speed serial: Gbps data rates

- Power delivery: Integrated power management

- Versatile connectivity: Replaces many protocols

Conclusion: Making the Right Choice

The choice between I2C and SPI ultimately depends on your specific application requirements, system constraints, and performance needs. Both protocols have stood the test of time and continue to be essential tools in the embedded systems designer's toolkit.

Choose I2C when you need:

- Maximum pin efficiency with multiple devices

- Built-in addressing and error handling

- Moderate speeds with good noise immunity

- Simple wiring and easy debugging

- Standard sensor interfaces

Choose SPI when you need:

- High-speed data transfer capabilities

- Full-duplex communication

- Simple, deterministic protocol behavior

- Maximum throughput for data-intensive applications

- Direct memory access (DMA) compatibility

Consider both protocols when:

- Building complex systems with diverse requirements

- Optimizing each interface for specific tasks

- Balancing performance and resource utilization

- Supporting legacy devices and future expansion

Remember that many successful embedded systems use both protocols strategically—I2C for sensor networks and configuration interfaces, SPI for high-performance data transfer and storage. The key is understanding each protocol's strengths and applying them where they provide the greatest benefit.

As embedded systems continue to evolve toward higher performance and greater connectivity, both I2C and SPI will remain fundamental building blocks, supplemented by newer protocols like I3C and advanced SPI variants. Master both protocols, understand their trade-offs, and you'll be well-equipped to design robust, efficient embedded systems for any application.

🔗 Related Posts

Credits