Last month, a manufacturing facility lost $50,000 in production when three critical conveyor motors failed within hours of each other. The culprit wasn't mechanical wear or age – it was voltage drop. The motors, struggling with inadequate voltage, had been slowly destroying themselves for months before the catastrophic failure.

If you're experiencing premature motor failures, overheating, or poor performance, voltage drop could be silently sabotaging your electrical systems. This guide reveals exactly how voltage drop affects motor performance and provides practical solutions to protect your investment.

The Hidden Cost of Motor Voltage Drop

Motor voltage drop issues cost U.S. industries over $2.8 billion annually in:

- Premature motor replacements

- Production downtime

- Energy waste from inefficient operation

- Increased maintenance costs

Unlike resistive loads that simply produce less heat or light with reduced voltage, motors respond dramatically to voltage variations, making them particularly vulnerable to voltage drop effects.

The Torque-Voltage Relationship

The fundamental problem lies in the physics of motor operation. For induction motors, the relationship between torque and voltage follows this critical equation:

Motor Torque ∝ (Applied Voltage)²

This square relationship means small voltage reductions cause disproportionately large torque losses:

| Voltage Drop % | Available Torque % | Torque Loss % | Performance Impact |

|---|

| 5% | 90.3% | 9.7% | Noticeable sluggishness |

| 10% | 81.0% | 19.0% | Significant performance loss |

| 15% | 72.3% | 27.7% | Severe operational issues |

| 20% | 64.0% | 36.0% | Motor may not start |

Real-World Calculation Example

Consider a 10 HP motor rated for 460V experiencing a 7% voltage drop:

Normal Operation:

- Applied voltage: 460V

- Available torque: 100%

With 7% Voltage Drop:

- Applied voltage: 460V - (460V × 0.07) = 427.8V

- Available torque: (427.8V ÷ 460V)² = 86.7%

- Torque loss: 13.3%

This 13.3% torque reduction can prevent proper startup, cause stalling under load, or force the motor to operate at dangerous current levels.

Motor Types and Voltage Drop Sensitivity

Single-Phase Motors

Single-phase motors are particularly sensitive to voltage drop due to their starting characteristics:

Starting Torque Impact:

- 10% voltage drop = 19% reduction in starting torque

- 15% voltage drop = 28% reduction in starting torque

- May fail to start high-inertia loads

Common Applications Affected:

- HVAC compressors

- Well pumps

- Shop equipment

- Residential appliances

Three-Phase Induction Motors

Three-phase motors handle voltage drop better than single-phase but still suffer significant effects:

| Motor Size (HP) | Critical Voltage Drop % | Typical Symptoms |

|---|

| 1-5 HP | 8-10% | Hard starting, overheating |

| 5-25 HP | 10-12% | Reduced efficiency, current increase |

| 25-100 HP | 12-15% | Significant performance loss |

| 100+ HP | 15%+ | May trip protection devices |

Variable Frequency Drive (VFD) Considerations

Motors controlled by VFDs have different voltage drop responses:

Advantages:

- VFDs can compensate for moderate voltage drop

- Better torque control at low speeds

- Built-in voltage monitoring

Limitations:

- Severe voltage drop can cause VFD faults

- Reduced efficiency at low input voltages

- May trigger undervoltage protection

Comprehensive Motor Voltage Drop Troubleshooting Guide

Step 1: Symptom Identification Checklist

Performance Symptoms:

Electrical Symptoms:

Step 2: Voltage Measurements

Required Equipment:

- Digital multimeter (true RMS for AC)

- Clamp meter for current measurement

- Non-contact voltage tester for safety

Measurement Points:

- Source voltage (at electrical panel)

- Motor control panel (before contactors/starters)

- Motor terminals (at motor connection box)

- During starting (capture voltage sag)

- Under full load (running conditions)

Critical Measurements:

| Measurement Point | Acceptable Range | Action Required |

|---|

| No-load voltage | Within 2% of nominal | Monitor if higher |

| Starting voltage | Within 15% of nominal | Investigate if lower |

| Running voltage | Within 5% of nominal | Correct if lower |

Step 3: Current Analysis

High current with low voltage indicates voltage drop issues:

Calculation:

Expected Current = Rated HP × 746 ÷ (√3 × Voltage × Efficiency × PF)

Red Flags:

- Current >110% of rated current

- Current imbalance >10% between phases

- Increasing current trend over time

Step 4: Power Quality Assessment

Power Factor Impact:

Low power factor increases current, worsening voltage drop:

Apparent Current = Real Power ÷ (Voltage × Power Factor)

Harmonic Considerations:

- Non-linear loads increase effective resistance

- Harmonics can cause additional heating

- May require harmonic analysis equipment

Proven Solutions for Motor Voltage Drop Problems

Solution 1: Conductor Sizing Optimization

Immediate Action:

Calculate required conductor size using our complete voltage drop calculation guide.

Quick Reference Table:

| Motor HP | Distance (ft) | Min. Copper AWG | Recommended AWG |

|---|

| 5 HP | 100 | 8 | 6 |

| 10 HP | 100 | 6 | 4 |

| 25 HP | 100 | 2 | 1/0 |

| 50 HP | 100 | 1/0 | 3/0 |

Based on 3% voltage drop limit, 460V, 3-phase

Solution 2: Voltage Regulation Equipment

Buck-Boost Transformers:

- Cost-effective for single motors

- Provides 5-20% voltage adjustment

- Easy retrofit installation

Automatic Voltage Regulators (AVR):

- Maintains constant voltage output

- Protects multiple motors

- Higher initial cost but comprehensive protection

Motor Starting Equipment:

| Starting Method | Voltage Drop Reduction | Best For |

|---|

| Soft starters | 50-70% reduction | General applications |

| Star-delta starters | 67% reduction | High-inertia loads |

| Auto-transformers | 50-80% reduction | Large motors |

Solution 3: Power Factor Correction

Capacitor Banks:

Installing power factor correction capacitors reduces current and voltage drop:

Benefits:

- Reduces apparent current by 10-30%

- Improves voltage regulation

- Reduces utility demand charges

- Extends equipment life

Sizing Formula:

Required KVAR = KW × (tan φ₁ - tan φ₂)

Where φ₁ = existing power factor angle, φ₂ = desired power factor angle

Solution 4: System Redesign Strategies

Load Distribution:

- Balance loads across phases

- Relocate motors closer to source

- Install local step-down transformers

Dedicated Circuits:

- Separate large motors from lighting circuits

- Install dedicated feeders for critical equipment

- Consider on-site generation for large loads

Advanced Motor Protection Strategies

Smart Motor Protection Relays

Modern protection relays monitor multiple parameters:

Key Features:

- Undervoltage protection

- Phase loss detection

- Current imbalance monitoring

- Thermal protection

- Historical data logging

Predictive Maintenance Integration

Monitoring Parameters:

- Voltage trends

- Current signature analysis

- Vibration patterns

- Temperature profiles

Early Warning Signs:

- Gradual increase in operating current

- Voltage variations during starting

- Increased operating temperature

- Changes in power factor

Cost-Benefit Analysis of Voltage Drop Solutions

Investment Comparison

| Solution | Initial Cost | Installation | Annual Savings | Payback Period |

|---|

| Conductor upgrade | $500-5,000 | Moderate | $200-2,000 | 2-4 years |

| Buck-boost transformer | $1,000-3,000 | Easy | $300-1,500 | 2-3 years |

| Power factor correction | $2,000-10,000 | Complex | $500-5,000 | 2-4 years |

| VFD installation | $3,000-15,000 | Moderate | $1,000-8,000 | 2-5 years |

Costs vary by motor size and application

Energy Savings Calculation

Annual Energy Waste from Voltage Drop:

Energy Loss (kWh) = Motor HP × 0.746 × Hours × Efficiency Loss %

Annual Cost = Energy Loss × Electricity Rate ($/kWh)

Design Guidelines

Voltage Drop Limits:

- Motor starting: 15% maximum

- Motor running: 5% maximum (3% preferred)

- Critical applications: 2% maximum

Conductor Selection:

- Use copper for long runs

- Consider ambient temperature derating

- Include future load expansion in sizing

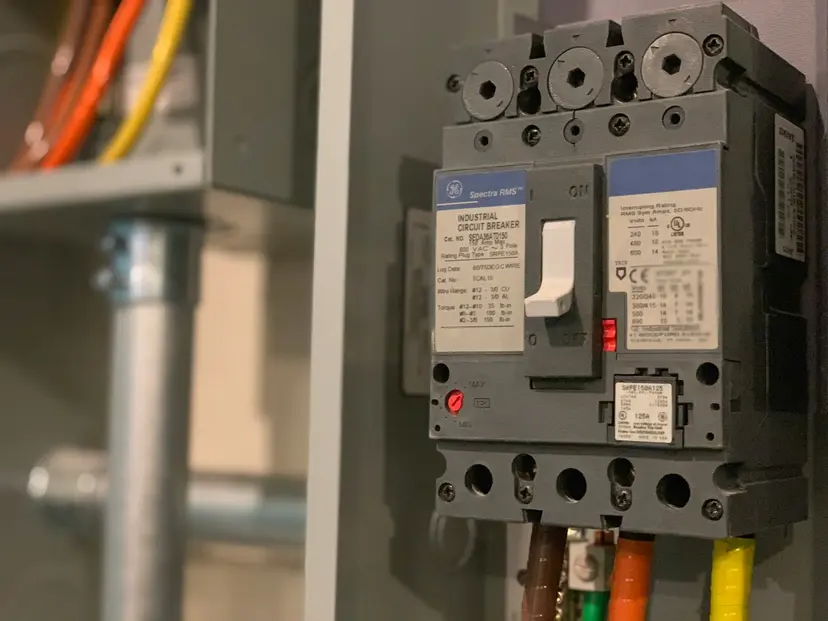

Circuit Protection:

- Size overloads for actual running current

- Use motor-rated circuit breakers

- Install monitoring equipment for critical motors

Code Requirements

National Electrical Code (NEC) Guidelines:

- Article 430: Motors and motor circuits

- Article 240: Overcurrent protection

- Article 310: Conductor sizing and derating

Key Requirements:

- Motor circuits must be sized for 125% of motor full-load current

- Branch circuit protection must be sized per NEC tables

- Overload protection must be 115-125% of nameplate current

Take Action: Protect Your Motors Today

Don't wait for costly motor failures to address voltage drop issues. Here's your immediate action plan:

- Audit critical motors - Measure voltage drop on your most important equipment

- Document symptoms - Create a baseline for performance comparison

- Calculate costs - Determine potential savings from voltage drop correction

Short-term Actions (This Month):

- Prioritize corrections - Start with motors showing highest voltage drop

- Get quotes - Compare solutions from qualified electrical contractors

- Plan implementation - Schedule corrections during maintenance windows

Long-term Strategy (Next Quarter):

- Implement monitoring - Install permanent voltage monitoring equipment

- Develop procedures - Create maintenance procedures for voltage drop testing

- Train staff - Ensure maintenance personnel understand voltage drop effects

Conclusion: Your Motors Deserve Better

Motor voltage drop isn't just a technical issue – it's a business problem that affects your bottom line every day. With the knowledge and tools provided in this guide, you can:

- Identify voltage drop problems before they cause failures

- Calculate the exact impact on your motor performance

- Implement cost-effective solutions that pay for themselves

- Protect your investment in motor-driven equipment

Ready to Solve Your Voltage Drop Problems?

Start with our comprehensive voltage drop calculation guide to master the fundamentals, then use our voltage drop calculator to analyze your specific motor circuits.

Need Expert Help? Voltage drop problems can be complex, especially in industrial applications. When in doubt, consult with a licensed electrical engineer or qualified electrical contractor to ensure safe, code-compliant solutions.

Resources for Further Learning:

Remember: Electrical work should always be performed by qualified professionals. This guide is for educational purposes and should not replace proper engineering analysis or professional electrical consultation.

Credits