Understanding power distribution panels is essential for anyone involved in electrical system design, installation, or maintenance. Whether you're upgrading your home's electrical service, designing a commercial facility, or managing an industrial power system, selecting and sizing the right electrical distribution panel ensures safe, reliable, and efficient power distribution throughout your building.

From residential 100-amp panels to massive 600 amp main distribution panels in commercial facilities, this comprehensive guide will help you understand distribution board types, sizing calculations, and installation requirements to make informed decisions about your electrical infrastructure.

Understanding Power Distribution Panels

What is a Power Distribution Panel?

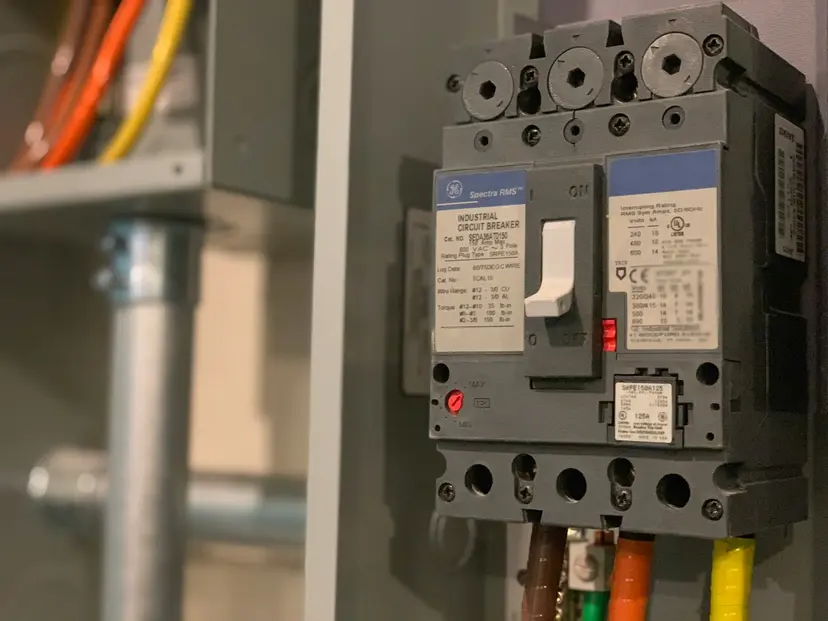

A power distribution panel (also called an electrical distribution panel, distribution board, or consumer unit in UK/European markets) is the central hub of any electrical system. It receives incoming electrical power from the utility or main service and distributes it safely to various circuits throughout a building through protective devices like circuit breakers or fuses.

Primary Functions:

- Power Distribution: Routes electricity from service entrance to individual circuits

- Circuit Protection: Houses circuit breakers that protect against overloads and short circuits

- Load Management: Organizes and balances electrical loads across phases

- Safety Control: Provides centralized disconnect capability for maintenance and emergencies

- Metering Integration: Often includes or connects to electrical metering equipment

Distribution Panel vs Consumer Unit

These terms are often used interchangeably, but there are regional preferences:

| Term | Region | Common Usage | Technical Difference |

|---|

| Distribution Panel | North America | Commercial/Industrial | Larger, modular systems |

| Consumer Unit | UK/Europe | Residential | Compact, integrated design |

| Distribution Board | Universal | All applications | General technical term |

| Load Center | North America | Residential | Small residential panels |

Key Point: While terminology varies by region, all serve the same fundamental purpose of safely distributing electrical power and protecting circuits.

Types of Power Distribution Panels

Main Distribution Panel (MDP)

The main distribution panel is the first point of power distribution from the utility service entrance.

Characteristics:

- Includes a main service disconnect breaker

- Receives power directly from the utility transformer

- Typical residential ratings: 100A, 150A, 200A, 400A

- Common commercial and industrial ratings: 400A, 600A, 800A, 1200A+

- Must comply with NEC Article 408 (or local equivalent standards)

Common Applications:

- Single-family homes (100–200A)

- Multi-family buildings (400–800A)

- Commercial facilities (600A+)

- Industrial plants (1200A+)

Sub-Distribution Panel (Subpanel)

A sub-distribution panel is fed from the main panel and distributes power to specific building areas or equipment groups.

Characteristics:

- Fed through breaker in main panel

- No main disconnect breaker required (NEC allows but not required)

- Separate grounding and neutral buses

- Sizes typically 60A-200A

When to Use Subpanels:

- Home additions or renovations

- Detached garages or workshops

- Specific equipment clusters

- Long distance from main panel

- To organize circuits by function or location

3 Phase Consumer Unit

A 3 phase consumer unit (or three-phase distribution board) is designed specifically for three-phase electrical systems common in commercial and industrial applications.

Key Features:

- Three separate phase bus bars (L1, L2, L3)

- Balanced load distribution capability

- Higher power capacity than single-phase

- Support for both three-phase and single-phase loads

Voltage Configurations:

- 208V/120V (North America commercial)

- 480V/277V (North America industrial)

- 400V/230V (European standard)

- 415V/240V (UK/Australia standard)

Applications Requiring 3-Phase:

- Industrial motors and machinery

- Large commercial HVAC systems

- Data centers and server rooms

- Manufacturing facilities

- Large commercial kitchens

- Electric vehicle charging stations (multiple)

Distribution Panel Components

Essential Panel Elements

Understanding the components inside an electrical distribution panel helps with maintenance, troubleshooting, and upgrade planning.

| Component | Function | Importance |

|---|

| Main Breaker | Disconnects entire panel | Primary safety disconnect |

| Bus Bars | Conducts electricity to breakers | Current distribution backbone |

| Circuit Breakers | Protects individual circuits | Overcurrent protection |

| Neutral Bus | Common connection for neutral wires | Completes electrical path |

| Ground Bus | Equipment grounding connection | Safety grounding system |

| Panel Enclosure | Houses all components | Physical protection, safety |

Bus Bar Configurations

Single-Phase Panel (120/240V)

- Two hot buses: L1 and L2 at 120V each

- Neutral bus: Common return path

- Ground bus: Equipment grounding

- 240V loads: Connect to both hot buses

- 120V loads: Connect to one hot bus and neutral

3-Phase Panel (208V/120V or 480V/277V)

- Three hot buses: L1, L2, and L3

- Neutral bus: For single-phase loads

- Ground bus: Equipment grounding

- 3-phase loads: Connect to all three phases

- Single-phase loads: Connect between any phase and neutral

Distribution Panel Sizing Guide

Load Calculation Fundamentals

Proper panel sizing begins with accurate load calculations following NEC Article 220.

Step 1: Calculate Total Connected Load

General Lighting and Receptacles:

Lighting Load (VA)=Square Footage×3 VA/ft2

Small Appliance Circuits:

- Minimum 2 circuits at 1500 VA each = 3000 VA

- Kitchen countertop outlets

Laundry Circuit:

- Minimum 1 circuit at 1500 VA

Large Appliances (Nameplate Ratings):

- Electric range: 8000-12,000 VA

- Electric dryer: 5000-6000 VA

- Water heater: 3500-5500 VA

- HVAC equipment: Per nameplate

Step 2: Apply Demand Factors

NEC allows demand factors for certain loads since not all loads operate simultaneously:

| Load Type | Demand Factor |

|---|

| General lighting first 3000 VA | 100% |

| General lighting over 3000 VA | 35% |

| Electric range 12 kW or less | 8000 VA |

| Electric dryer | 100% (5000 VA min) |

| Water heater | 100% |

| HVAC (largest) | 100% |

Step 3: Calculate Service/Panel Size

Example Calculation - Residential Home:

Given:

- 2400 sq ft home

- Standard appliances

- Central AC: 24A at 240V

- Electric range: 12 kW

- Electric dryer: 5.5 kW

- Water heater: 4.5 kW

Calculations:

Lighting Load:

2400 ft2×3 VA/ft2=7200 VA

Small Appliance & Laundry:

3 circuits×1500 VA=4500 VA

General Lighting with Demand Factor:

- First 3000 VA: 3000 VA × 100% = 3000 VA

- Remaining: (7200 + 4500 - 3000) × 35% = 3045 VA

- Subtotal: 6045 VA

Large Appliances:

- Electric range: 8000 VA (demand factor applied)

- Dryer: 5500 VA × 100% = 5500 VA

- Water heater: 4500 VA × 100% = 4500 VA

- Central AC: 24A × 240V = 5760 VA

Total Load:

6045+8000+5500+4500+5760=29,805 VA

Required Service Size:

Amperage=240 V29,805 VA=124.2 A

Add 25% for Future Expansion:

124.2×1.25=155 A

Panel Selection: 200 Amp Main Distribution Panel (next standard size)

Standard Panel Sizes and Applications

| Panel Size | Voltage | Typical Application | Number of Circuits |

|---|

| 100 Amp | 120/240V | Small homes, older construction | 20-30 spaces |

| 150 Amp | 120/240V | Medium homes, limited electric appliances | 30-40 spaces |

| 200 Amp | 120/240V | Modern homes, standard loads | 40-60 spaces |

| 400 Amp | 120/240V or 208V | Large homes, multi-family buildings | 60+ spaces |

| 600 Amp | 208V or 480V | Commercial buildings, light industrial | 84+ spaces |

| 800 Amp | 208V or 480V | Large commercial, industrial facilities | 100+ spaces |

600 Amp Main Distribution Panel Applications

A 600 amp main distribution panel is a heavy-duty power distribution solution for facilities with substantial electrical demands.

Typical Applications:

- Large Commercial Buildings: Office complexes, shopping centers

- Industrial Facilities: Light manufacturing, warehouse operations

- Multi-Unit Residential: Apartment buildings (20+ units)

- Data Centers: Server farms with high density computing

- Hospitals and Healthcare: Medical facilities with critical loads

- Educational Facilities: Schools, universities with labs

Installation Considerations:

- Requires 600 kcmil to 1250 kcmil service entrance conductors

- Three-phase service typical (208V or 480V)

- Multiple subpanel feeders

- May require current transformer metering

- Professional engineering design required

- Utility coordination for service connection

Distribution Panel Selection Criteria

Factor 1: Load Requirements

Calculate Your Actual Needs:

- Sum all connected loads

- Apply appropriate demand factors

- Add 20-25% for growth

- Select next standard size up

Factor 2: Number of Circuits Needed

Consider current and future circuit requirements:

- Count existing circuits

- Add planned additions (10-15 years)

- Include spare spaces (20% minimum)

- Consider dedicated circuits for:

- Kitchen appliances

- Bathroom outlets

- Laundry equipment

- HVAC systems

- Electric vehicle charging

Factor 3: Phase Configuration

Single-Phase (120/240V):

- Most residential applications

- Light commercial use

- Loads up to 200A typical

- Simple wiring and installation

Three-Phase (208V/120V or 480V/277V):

- Commercial and industrial

- Motors over 3 HP

- Large HVAC systems

- Balanced load distribution

- Higher power efficiency

Factor 4: Panel Type and Features

Standard Features:

- Main breaker disconnect

- Branch circuit breakers

- Neutral and ground buses

- NEMA 1 enclosure (indoor)

Optional Features:

- GFCI/AFCI breakers

- Surge protection

- Remote monitoring capability

- Outdoor-rated enclosures (NEMA 3R)

- Generator interlock kits

- Smart home integration

Installation Requirements and Codes

NEC Code Requirements

Article 408: Switchboards and Panelboards

Working Space Requirements (NEC 110.26):

- Depth: Minimum 3 feet in front of panel

- Width: 30 inches or width of panel (whichever is greater)

- Height: 6.5 feet minimum working space

- No Storage: Working space must remain clear

Panel Height Requirements:

- Maximum height to center of grip: 6 feet 7 inches

- Minimum height above floor: 4 feet to top breaker

- ADA accessible where required

Grounding and Bonding (NEC Article 250)

Main Panel:

- Neutral and ground bonded together

- Main bonding jumper installed

- Grounding electrode system connected

Subpanel:

- Neutral and ground kept separate

- Four-wire feeder from main panel

- Equipment ground only to panel enclosure

Professional Installation Requirements

When Licensed Electrician Required:

- All service entrance work

- Main panel installation or replacement

- Panel upgrades requiring utility connection

- Three-phase distribution systems

- Any work requiring permits

Permit Requirements:

- Service upgrades (amperage increase)

- New panel installations

- Subpanel additions in many jurisdictions

- Panel relocations

Distribution Panel Maintenance

Routine Inspection Schedule

Monthly Checks

- Test GFCI/AFCI breakers (test button)

- Listen for unusual sounds (buzzing, crackling)

- Check for burning odors

- Verify panel door closes securely

Annual Professional Inspection

- Infrared thermography scan

- Tighten bus bar and lug connections

- Clean dust and debris

- Check breaker operation

- Verify proper labeling

- Inspect for signs of overheating

Call an Electrician If You Notice:

- Burning smell from panel

- Hot panel enclosure or breakers

- Breakers frequently tripping

- Buzzing or crackling sounds

- Visible corrosion on connections

- Flickering lights throughout building

- Discolored breakers or wires

- Loose or damaged panel components

Panel Lifespan and Replacement

Typical Service Life:

- Modern panels: 25-40 years

- Older Federal Pacific or Zinsco: Replace immediately (safety hazard)

- Fuse boxes: Consider upgrading to breakers

Upgrade Indicators:

- Insufficient circuit capacity

- Adding major appliances (EV charger, pool)

- Home addition or renovation

- Federal Pacific or Zinsco panels

- Aluminum wiring connections

- Obsolete or discontinued breakers

Upgrading Your Distribution Panel

Common Upgrade Scenarios

Scenario 1: 100A to 200A Service Upgrade

What's Involved:

- New 200A main panel installation

- Service entrance conductor replacement

- Utility meter base upgrade

- Main breaker upgrade

- Permit and inspection

- Estimated Typical Cost: $2,000-$4,000 (residential)

Scenario 2: Adding Subpanel

What's Involved:

- Feeder circuit from main panel

- Proper wire sizing for distance

- Subpanel installation

- Separate neutral and ground buses

- Circuit organization

- Estimated Typical Cost: Around $500-$1,500 (not including extended wiring runs or complex installations)

Scenario 3: Single-Phase to 3-Phase Conversion

What's Involved:

- Utility service upgrade coordination

- New 3 phase consumer unit installation

- Service entrance upgrades

- Load balancing across phases

- Equipment compatibility verification

- Estimated Typical Cost: Around $5,000-$15,000+ (varies significantly by property and utility requirements)

Cost Factors

| Factor | Impact on Cost |

|---|

| Panel size/amperage | Higher amps = higher cost |

| Service entrance upgrade | Major cost component |

| Utility coordination | May include utility fees |

| Permit and inspection | $100-$500 typically |

| Location accessibility | Difficult access increases cost |

| Existing panel removal | Disposal and labor costs |

Distribution Panel Safety

Electrical Safety Practices

Before Working Near Panel:

- Never open panel unless you're qualified

- Assume all wires are live even with main breaker off

- Keep working space clear at all times

- Post proper labeling on all circuits

- Use proper PPE if qualified to work

Emergency Procedures:

- Know main breaker location

- Keep flashlight near panel

- Post emergency numbers

- Train household members

- Test monthly for awareness

Circuit Labeling Best Practices

Proper Circuit Identification:

- Label each breaker clearly

- Include room and outlets/fixtures served

- Use waterproof labels

- Update after any changes

- Create circuit map document

Example Labels:

- "Kitchen Countertop Outlets - North Wall"

- "Master Bedroom - All Outlets & Lights"

- "Central AC Compressor - Outdoor Unit"

- "Electric Range - Kitchen"

Advanced Distribution Systems

Smart Distribution Panels

Modern technology is transforming electrical distribution:

Smart Panel Features:

- Real-time monitoring: Track energy usage by circuit

- Remote control: Turn circuits on/off via smartphone

- Load management: Automatically balance loads

- Integration: Works with home automation systems

- Predictive maintenance: Alerts for potential issues

Popular Smart Panel Systems:

- Span Panel

- Schneider Electric Square D with Wiser

- Eaton Smart Breakers

- Siemens Smart Panels

Generator Integration

Transfer Switch Options:

Manual Transfer Switch:

- Manual switching between utility and generator

- Lower cost option

- Requires user intervention

- Common for portable generators

Automatic Transfer Switch (ATS):

- Automatic switching when power fails

- Seamless transition

- Works with standby generators

- Higher cost but convenient

Generator Interlock Kit:

- Mechanical device on panel

- Prevents simultaneous utility/generator connection

- Lower cost than transfer switch

- Requires manual generator start

Distribution Panel Comparison Table

Residential Panel Comparison

| Panel Type | Amperage | Best For | Circuit Capacity | Estimated Typical Cost |

|---|

| Basic Load Center | 100A | Small homes or light electrical demand | 20–30 circuits | Around $150–$300 |

| Standard Main Panel | 200A | Modern homes with standard appliances | 40–60 circuits | Approximately $300–$600 |

| Main Lug Panel | 100–200A | Subpanel applications, no main breaker | 20–40 circuits | Typically $200–$400 |

| Three-Phase Panel | 200–400A | Larger homes, workshops, or heavy equipment | 40–60 circuits | Usually $800–$2,000+ |

Commercial Panel Comparison

| Panel Type | Amperage | Best For | Voltage | Estimated Typical Cost |

|---|

| Commercial Panel | 400A | Small commercial buildings or light industrial loads | 208V / 120V | Around $1,500–$3,000 |

| Distribution Board | 600A | Medium-sized commercial facilities | 208V or 480V | Approximately $3,000–$6,000 |

| Switchboard | 800–1200A | Large commercial or industrial applications | 480V | Typically $8,000–$15,000+ |

Troubleshooting Common Panel Issues

Problem: Breaker Keeps Tripping

Possible Causes:

- Overloaded circuit: Too many devices on one circuit

- Short circuit: Damaged wire or appliance fault

- Ground fault: Current leaking to ground

- Defective breaker: Breaker itself is faulty

Solutions:

- Redistribute loads across circuits

- Unplug devices and test systematically

- Inspect for damaged cords or outlets

- Replace defective breaker

Problem: Warm or Hot Panel

Possible Causes:

- Loose connections creating resistance

- Overloaded circuits

- Undersized panel for load

- Failing breaker or bus bar

Action Required:

- Immediate: Reduce load on circuits

- Urgent: Call licensed electrician

- Do not: Ignore this warning sign

- Risk: Potential fire hazard

Problem: Insufficient Circuit Capacity

Solutions:

- Add subpanel: Expand circuit capacity

- Upgrade main panel: Increase amperage

- Redistribute loads: Balance existing circuits

- Remove unused circuits: Free up spaces

Conclusion: Selecting the Right Distribution Panel

Choosing and sizing the right power distribution panel is critical for electrical safety, system reliability, and future expandability. Whether you need a simple residential distribution board, a sophisticated 3 phase consumer unit for industrial equipment, or a robust 600 amp main distribution panel for a commercial facility, understanding load calculations, code requirements, and panel features ensures you make the right choice.

Key Takeaways:

- Calculate loads accurately using NEC methods and demand factors

- Size for future growth by adding 20-25% spare capacity

- Choose appropriate phase configuration (single or three-phase) based on loads

- Consider circuit quantity including future expansion needs

- Always use licensed professionals for service entrance and main panel work

- Maintain proper documentation including circuit labels and load schedules

Whether you're upgrading from an outdated 100-amp panel to a modern 200-amp service, installing a subpanel for a home addition, or designing a complete electrical distribution system for a new commercial building, following proper sizing procedures and code requirements ensures a safe, reliable electrical system that serves your needs today and adapts to future demands.

For more detailed information on related electrical topics, explore our guides on circuit breaker sizing, wire sizing calculations, and voltage drop considerations.

🔗 Related Posts

Helpful Calculators

Credits