Installing a 50 amp circuit requires precise wire sizing to ensure safety, code compliance, and reliable operation. Whether you're wiring a hot tub, electric range, RV outlet, or sub-panel, choosing the correct wire size for your 50 amp breaker is critical to prevent overheating, electrical fires, and equipment damage.

Using the wrong wire size is one of the most dangerous electrical mistakes. Undersized wire will overheat before the breaker trips, creating a fire hazard, while oversized wire wastes money without providing additional safety. This comprehensive guide provides everything you need to properly size, select, and install wire for 50 amp circuits, including detailed charts, NEC code requirements, and practical installation tips.

Quick Answer: Wire Size for 50 Amp Breaker

For a 50 amp breaker, the required wire sizes are:

- Copper Wire: 6 AWG minimum

- Aluminum Wire: 4 AWG minimum

- Insulation Rating: 90°C (THWN-2, XHHW-2, or equivalent)

- Applies to: Both 120V and 240V circuits

These sizes assume standard installation conditions (ambient temperature ≤ 86°F, no more than three current-carrying conductors in conduit). Derating may be required for high temperatures or conduit fill.

Table of Contents

- Understanding 50 Amp Circuit Requirements

- Wire Size Charts for 50 Amp Breakers

- Copper vs. Aluminum Wire Selection

- Voltage Considerations: 120V vs 240V

- Common 50 Amp Circuit Applications

- NEC Code Requirements and Compliance

- Installation Guide and Best Practices

- Voltage Drop and Distance Calculations

Understanding 50 Amp Circuit Requirements

What is a 50 Amp Circuit?

A 50 amp circuit is designed to safely carry up to 50 amperes of electrical current continuously. The circuit breaker protects the wire from overcurrent conditions by tripping when current exceeds 50 amps, preventing wire overheating and potential fires.

Power Capacity:

- At 120V: 6,000 watts (50A × 120V = 6,000W)

- At 240V: 12,000 watts (50A × 240V = 12,000W)

Why Wire Size Matters

The wire must have sufficient ampacity (current-carrying capacity) to handle 50 amps without overheating. Using undersized wire creates serious safety hazards:

| Wire Condition | Consequence |

|---|

| Undersized (too small) | Wire overheats before breaker trips - FIRE HAZARD |

| Correctly sized | Safe operation within temperature limits |

| Oversized (too large) | No safety benefit, increased cost and installation difficulty |

⚠️ Critical Safety Warning: Never use wire smaller than required for a 50 amp breaker. The most common dangerous mistake is using 8 AWG copper wire (rated for only 40 amps) on a 50 amp breaker. This creates an immediate fire hazard as the wire will melt before the breaker trips.

Wire Ampacity Fundamentals

Wire ampacity depends on:

- Conductor material: Copper vs. aluminum

- Wire gauge (AWG): Smaller numbers = larger wire = higher capacity

- Insulation rating: 60°C, 75°C, or 90°C

- Installation conditions: Temperature, conduit fill, bundling

Wire Size Charts for 50 Amp Breakers

Standard Wire Sizing Table

The following chart shows minimum wire sizes for 50 amp circuits under standard conditions:

| Wire Gauge | Material | Ampacity at 75°C | Ampacity at 90°C | Suitable for 50A? |

|---|

| 8 AWG | Copper | 40A | 50A* | ❌ Not recommended |

| 6 AWG | Copper | 55A | 65A | ✅ Yes - Standard choice |

| 4 AWG | Copper | 70A | 85A | ✅ Yes - For long runs |

| 8 AWG | Aluminum | 30A | 40A | ❌ No |

| 6 AWG | Aluminum | 40A | 50A* | ❌ Not recommended |

| 4 AWG | Aluminum | 55A | 65A | ✅ Yes - Standard for aluminum |

| 2 AWG | Aluminum | 75A | 90A | ✅ Yes - For long runs |

Note: While 8 AWG copper shows 50A at 90°C, this is only for wire ampacity rating. Per NEC requirements, circuit breakers are derated to 75°C column, making 6 AWG the minimum safe choice.

Recommended Wire Sizes by Application

| Application | Copper Wire | Aluminum Wire | Notes |

|---|

| Standard 50A Circuit | 6 AWG | 4 AWG | Up to 50 feet |

| Long Runs (75-100 ft) | 4 AWG | 2 AWG | Minimizes voltage drop |

| Hot Tub (240V) | 6 AWG | 4 AWG | Direct burial rated |

| Electric Range | 6 AWG | 4 AWG | Usually 8/3 or 6/3 cable |

| RV Outlet | 6 AWG | 4 AWG | NEMA 14-50R receptacle |

| Sub-Panel Feeder | 6 AWG (50A) | 4 AWG (50A) | Consider future expansion |

Copper vs. Aluminum Wire Selection

Copper Wire Benefits

Advantages:

- Higher conductivity (requires smaller wire size)

- Easier to work with and terminate

- No special compounds required

- Better long-term reliability

- Preferred by most electricians

For 50 Amp Circuits:

- Wire Size: 6 AWG minimum

- Cable Types:

- 6/2 with ground (120V circuits)

- 6/3 with ground (240V circuits - most common)

- Cost: More expensive than aluminum

- Weight: Lighter and easier to handle than equivalent aluminum

Aluminum Wire Considerations

Advantages:

- Lower material cost (30-50% cheaper)

- Lighter weight for very large sizes

- Adequate for most applications when properly installed

Requirements for Aluminum:

- Wire Size: 4 AWG minimum (two sizes larger than copper)

- Anti-oxidant Compound: Required at all connections

- CO/ALR Rated: All devices must be rated for aluminum

- Torque Specifications: Must follow manufacturer torque requirements

- Expansion/Contraction: More sensitive to thermal cycling

💡 Professional Recommendation: For residential 50 amp circuits, copper wire (6 AWG) is strongly recommended despite higher cost. Aluminum requires special installation procedures that many homeowners aren't equipped to handle properly, and improper installation can create fire hazards over time.

Voltage Considerations: 120V vs 240V

120V Circuits (Single Phase)

Wire Configuration:

- Hot conductor: Black (6 AWG)

- Neutral conductor: White (6 AWG)

- Ground conductor: Green or bare copper (6 AWG or smaller)

Power Capacity:

P=V×I=120V×50A=6,000 watts

Common Applications:

- Large power tools

- Heavy-duty appliances

- Industrial equipment

Cable Type: 6/2 with ground (black, white, bare)

240V Circuits (Split Phase)

Wire Configuration:

- Hot conductor 1: Black (6 AWG)

- Hot conductor 2: Red (6 AWG)

- Neutral conductor: White (6 AWG) - if required

- Ground conductor: Green or bare copper (6 AWG or smaller)

Power Capacity:

P=V×I=240V×50A=12,000 watts

Common Applications:

- Electric ranges and cooktops

- Hot tubs and spas

- Large air conditioners

- EV charging stations

Cable Types:

- 6/3 with ground (black, red, white, bare) - for appliances requiring neutral

- 6/2 with ground (black, red, bare) - for loads not requiring neutral

Voltage Selection Impact

| Voltage | Current for Same Power | Wire Requirements | Efficiency |

|---|

| 120V | Higher (2× current) | Same wire size | Lower (more voltage drop) |

| 240V | Lower (½ current) | Same wire size | Higher (less voltage drop) |

Example: For 10,000 watts:

- At 120V: Requires 83.3 amps (needs multiple circuits)

- At 240V: Requires 41.7 amps (single 50A circuit adequate)

Common 50 Amp Circuit Applications

1. Electric Ranges and Cooktops

Typical Requirements:

- Voltage: 240V

- Wire: 6/3 with ground (copper) or 4/3 (aluminum)

- Receptacle: NEMA 14-50R

- Breaker: 50 amp double-pole

Installation Notes:

- Requires neutral conductor for 120V clock/controls

- Must be hardwired or use range receptacle

- Check manufacturer specifications for exact requirements

2. Hot Tubs and Spas

Typical Requirements:

- Voltage: 240V

- Wire: 6 AWG copper (direct burial rated)

- Disconnect: Required within sight of hot tub

- GFCI: Required for safety

Special Considerations:

- Use UF-B cable for underground runs

- Maintain proper burial depth (typically 18-24")

- Bond all metal components

- Follow manufacturer wiring diagram

3. RV Electrical Service

Standard 50 Amp RV Service:

- Voltage: 120/240V split phase

- Wire: 6/3 with ground

- Receptacle: NEMA 14-50R (4-prong)

- Breaker: 50 amp double-pole

RV Power Distribution:

- Provides two 120V legs at 50 amps each

- Total capacity: 12,000 watts

- Not the same as a 50 amp single-phase 240V circuit

4. Electric Vehicle Charging Stations

Level 2 EV Charging (50 Amp):

- Voltage: 240V

- Wire: 6 AWG copper minimum

- Charging Rate: Typically 40 amps continuous (80% of 50A)

- Actual Delivery: ~9.6 kW charging

Installation Requirements:

- Dedicated circuit required

- GFCI protection may be required (check local codes)

- Consider 60A circuit for future higher-power vehicles

5. Sub-Panel Feeders

50 Amp Sub-Panel:

- Wire Size: 6 AWG copper minimum

- Consider: 4 AWG for longer runs or future expansion

- Grounding: Separate ground and neutral bars in sub-panel

- Application: Workshops, garages, detached buildings

NEC Code Requirements and Compliance

NEC Article 210: Branch Circuits

Key Requirements for 50 Amp Circuits:

-

Conductor Sizing (NEC 210.19)

- Minimum conductor ampacity must be ≥ 125% of continuous load

- For 50A breaker: Wire rated for ≥ 50 amps required

-

Overcurrent Protection (NEC 240.4)

- Circuit breaker rating must not exceed conductor ampacity

- 6 AWG copper: Protected at 55-65 amps (50A breaker acceptable)

- 4 AWG aluminum: Protected at 55-65 amps (50A breaker acceptable)

-

GFCI Requirements (NEC 210.8)

- Required for outdoor outlets

- Required for garages and unfinished basements

- Required for hot tubs and spa installations

NEC Article 250: Grounding and Bonding

Equipment Grounding:

- All 50 amp circuits require equipment grounding conductor

- Ground wire may be sized per NEC Table 250.122

- For 50A breaker: 10 AWG copper or 8 AWG aluminum ground minimum

Typical Grounding:

- Most installations use same size ground as circuit conductors

- NM cable includes appropriately sized ground wire

Temperature Rating Requirements

NEC 110.14(C):

- Terminations rated 75°C unless marked otherwise

- Use 75°C ampacity column for conductor sizing

- 90°C insulation allows for derating calculations

Installation Guide and Best Practices

Step-by-Step Installation Process

Step 1: Verify Load Requirements

Calculate actual load to confirm 50 amp circuit is appropriate:

Required Amperage=VoltageTotal Wattage

Example - Hot Tub:

- Load: 11,500 watts at 240V

- Current: 11,500W ÷ 240V = 47.9 amps

- Continuous operation: 47.9A × 1.25 = 59.9A

- Conclusion: 50A circuit is adequate for 11,500W load

Step 2: Select Wire and Cable

For Copper (Most Common):

- Choose 6/3 with ground NM-B cable (Romex) for indoor

- Choose 6/3 UF-B cable for direct burial outdoor runs

- Verify insulation rating (90°C preferred)

For Aluminum:

- Choose 4 AWG aluminum conductors

- Use anti-oxidant compound

- Verify all connections are CO/ALR rated

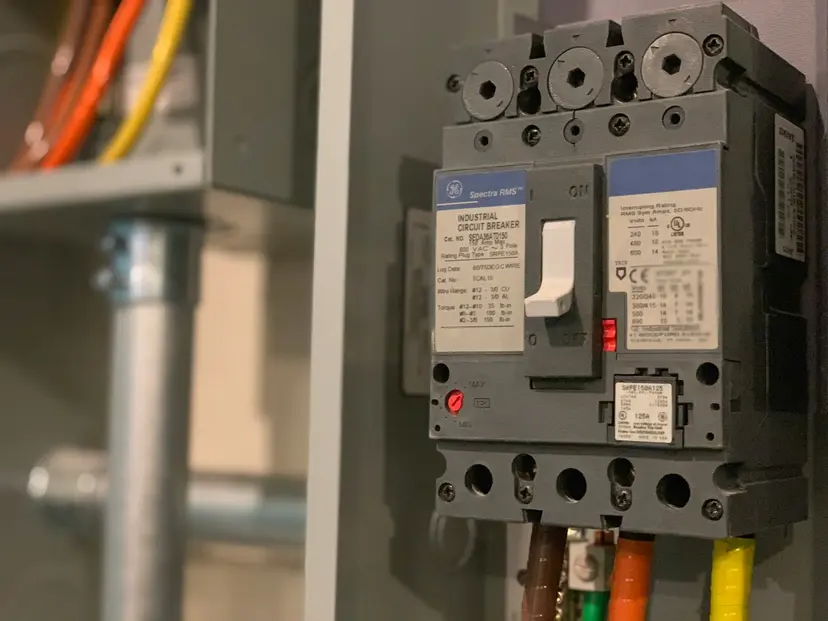

Step 3: Install Circuit Breaker

- Turn off main breaker - verify power is off with voltage tester

- Remove panel cover

- Install double-pole 50 amp breaker in appropriate slots

- Connect hot wires to breaker terminals (torque to spec)

- Connect neutral to neutral bus

- Connect ground to ground bus

Step 4: Run Cable

Indoor Installations:

- Secure cable every 4.5 feet and within 12" of boxes

- Protect cable through studs/joists with bushings

- Avoid sharp bends (minimum radius: 5× cable diameter)

- Leave 6-8" extra wire at boxes

Outdoor/Underground:

- Use proper burial depth (typically 18-24" for UF-B)

- Protect cable with conduit where exposed

- Install weatherproof boxes and fittings

- Seal all outdoor penetrations

Step 5: Make Connections

At Breaker Panel:

- Strip insulation carefully (don't nick copper)

- Insert conductors fully into terminals

- Tighten to manufacturer torque specifications

- Verify no bare copper exposed except ground

At Load/Receptacle:

- Match wire colors to terminal markings

- Black → brass terminal (hot)

- Red → brass terminal (hot) - if 240V

- White → silver terminal (neutral)

- Bare/green → green screw (ground)

Step 6: Test Installation

- Verify all connections are tight

- Check for proper polarity with voltage tester

- Test GFCI function (if applicable)

- Apply load and monitor operation

- Check for warm connections (infrared temp gun)

⚠️ Safety First: Always turn off power at the main breaker before working in electrical panels. Use a non-contact voltage tester to verify power is off. If you're not comfortable working with electrical systems, hire a licensed electrician. Improper wiring can cause fires, electric shock, or death.

Voltage Drop and Distance Calculations

Understanding Voltage Drop

Voltage drop is the reduction in voltage along a wire due to resistance. Excessive voltage drop causes:

- Poor appliance performance

- Overheating motors

- Light dimming

- Reduced equipment lifespan

Acceptable Voltage Drop:

- Branch circuits: 3% maximum (NEC recommendation)

- Combined feeder + branch: 5% maximum

- At 240V: 7.2V maximum drop for 3%

For single-phase circuits:

VD=CM2×K×I×L

Where:

- VD = Voltage drop in volts

- K = 12.9 (copper) or 21.2 (aluminum)

- I = Current in amperes

- L = One-way length in feet

- CM = Circular mils of conductor

Maximum Distance Chart for 50 Amp Circuits

For 6 AWG Copper Wire (26,240 CM) at 240V:

| Load Current | Max Distance for 3% VD | Voltage Drop at Max Distance |

|---|

| 50A (full load) | 54 feet | 7.2V (3%) |

| 40A (80% load) | 67 feet | 7.2V (3%) |

| 30A (60% load) | 89 feet | 7.2V (3%) |

For 4 AWG Copper Wire (41,740 CM) at 240V:

| Load Current | Max Distance for 3% VD | Voltage Drop at Max Distance |

|---|

| 50A (full load) | 86 feet | 7.2V (3%) |

| 40A (80% load) | 107 feet | 7.2V (3%) |

| 30A (60% load) | 143 feet | 7.2V (3%) |

When to Upsize Wire

Consider Using Larger Wire When:

- Distance exceeds values in chart above

- Powering sensitive electronic equipment

- Running motors (more sensitive to voltage drop)

- Local codes require lower voltage drop limits

Upsizing Benefits:

- Lower voltage drop

- Cooler operation

- Better efficiency

- Future expansion capability

Common Mistakes and How to Avoid Them

Mistake 1: Using 8 AWG Copper Wire

The Problem:

Many people see that 8 AWG copper is rated for 50 amps at 90°C and incorrectly assume it's suitable for a 50 amp breaker.

Why It's Wrong:

- NEC requires using 75°C column for terminations

- At 75°C, 8 AWG copper = 40 amps only

- Breaker terminals are typically 75°C rated

- Using 8 AWG creates fire hazard

The Solution:

Always use minimum 6 AWG copper or 4 AWG aluminum for 50 amp circuits, regardless of insulation temperature rating.

Mistake 2: Forgetting About Continuous Loads

The Problem:

Not applying the 125% factor for loads operating 3+ hours continuously.

Example:

- Hot tub draws 40 amps continuously

- 40A × 1.25 = 50A minimum circuit required

- Using 40A circuit would cause nuisance tripping

The Solution:

For continuous loads, multiply actual load by 1.25 to determine minimum circuit size. A 40-amp continuous load requires a 50-amp circuit minimum.

Mistake 3: Ignoring Voltage Drop on Long Runs

The Problem:

Installing properly sized wire for ampacity but ignoring voltage drop over distance.

Example:

- 100-foot run of 6 AWG copper

- 50 amp load at 240V

- Voltage drop: ~13V (5.4%) - TOO HIGH

The Solution:

Calculate voltage drop for your specific run length and upsize wire if necessary. For 100-foot run at 50 amps, use 4 AWG or 3 AWG copper.

Mistake 4: Improper Aluminum Wire Installation

The Problem:

Using aluminum wire without proper compounds, CO/ALR devices, or torque specifications.

Consequences:

- Loose connections

- Overheating at terminations

- Fire hazard

- Accelerated corrosion

The Solution:

When using aluminum wire:

- Apply anti-oxidant compound at all connections

- Use only CO/ALR rated devices

- Torque connections to specifications

- Use proper wire nuts (AL/CU rated)

- Inspect connections annually

Cost Comparison: Copper vs. Aluminum

| Component | Copper (6 AWG) | Aluminum (4 AWG*) | Approx. Difference |

|---|

| Wire / Cable | $250 – $350 | $150 – $220 | Save $100 – $130 |

| 50A Breaker | $30 – $50 | $30 – $50 | ~$0 |

| Receptacle / Junction | $15 – $30 | $20 – $40 | +$5 – $10 (Aluminum higher) |

| Anti-Oxidant Compound & Special Terminations | Included | $15 – $20 | +$15 – $20 |

| Labor (if hiring) | $200 – $400 | $250 – $450 | +$50 (Aluminum higher) |

| Total Material | $295 – $430 | $215 – $330 | Save ~$80 – $100 |

| Total + Labor | $495 – $830 | $465 – $780 | Save ~$30 – $50 |

*Aluminum conductor must use a larger gauge (e.g., 4 AWG vs 6 AWG copper) to achieve similar ampacity and voltage-drop performance.

Key Takeaways

- Material cost savings: around 20–30% when using aluminum.

- Labor cost: can partially offset savings due to extra work for connections and anti-oxidant application.

- Durability: copper offers better long-term reliability and less maintenance (fewer oxidation issues).

- DIY vs. Professional:

- DIY installations may benefit more from aluminum’s lower material cost.

- Professional electricians often prefer copper for longevity and fewer callbacks.

Notes & Assumptions

- Prices are approximate U.S. market averages; local costs may vary.

- Based on a 100-ft run, 50A load, with standard residential wiring conditions.

- Always confirm local electrical code and conductor size requirements before installation.

Conclusion: Ensuring Safe and Code-Compliant 50 Amp Circuits

Proper wire sizing for 50 amp breakers is non-negotiable for electrical safety. Whether you're installing a hot tub, electric range, RV outlet, or sub-panel feeder, always use minimum 6 AWG copper wire or 4 AWG aluminum wire with appropriate 90°C insulation rating. Never compromise on wire size, as undersized conductors create serious fire hazards that endanger lives and property.

Key Points to Remember:

- Minimum Wire Sizes: 6 AWG copper or 4 AWG aluminum for 50 amp circuits

- Never Use 8 AWG: Even though rated for 50A at 90°C, termination limitations require larger wire

- Consider Voltage Drop: For runs over 50-60 feet, upsize to 4 AWG copper or 2 AWG aluminum

- Follow NEC Requirements: Use 75°C ampacity ratings for conductor selection

- Apply Safety Factors: Multiply continuous loads by 125% when sizing circuits

- Professional Installation: When in doubt, hire a licensed electrician

Whether you choose copper for its ease of installation and reliability or aluminum for cost savings, proper installation techniques and code compliance ensure your 50 amp circuit operates safely for decades. Always verify local code requirements, obtain necessary permits, and have your work inspected by qualified authorities.

For more detailed information on circuit protection and wire sizing, explore our comprehensive guides on circuit breaker sizing and wire size calculations to master electrical system design and installation.

🔗 Related Posts

Helpful Calculators

Credits