Proper conduit fill is critical for electrical safety, code compliance, and system performance. Overfilling conduits causes excessive heat buildup, difficult wire pulling, and potential insulation damage, while oversizing wastes money and installation space. Understanding NEC conduit fill requirements ensures your electrical installations are safe, compliant, and efficient.

Whether you're installing residential branch circuits, commercial power distribution, or industrial control wiring, mastering conduit fill calculations is essential for every electrical professional. This guide provides the charts, calculations, and practical examples you need to size conduits correctly every time.

Table of Contents

- Understanding Conduit Fill Requirements

- NEC Conduit Fill Tables and Charts

- Step-by-Step Conduit Fill Calculations

- Quick Reference Wire Fill Charts

- Common Conduit Sizing Applications

- Best Practices and Code Compliance

Understanding Conduit Fill Requirements

Why Conduit Fill Matters

Proper conduit fill prevents three critical problems:

Heat Buildup: Overcrowded conductors trap heat, accelerating insulation degradation and increasing fire risk. Heat dissipation requires adequate air space around conductors.

Installation Difficulty: Overfilled conduits make wire pulling extremely difficult, often damaging insulation during installation. This leads to costly rework and potential safety hazards.

Code Violations: NEC Chapter 9 mandates maximum fill percentages. Violations can result in failed inspections, project delays, and liability issues.

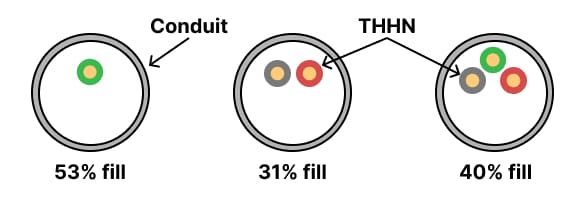

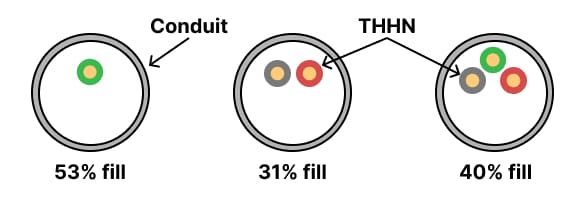

NEC Chapter 9 Fill Percentages

The National Electrical Code establishes maximum conduit fill based on conductor count:

| Number of Conductors | Maximum Fill Percentage | Typical Applications |

|---|

| 1 conductor | 53% | Large service entrances, feeders |

| 2 conductors | 31% | Split-phase circuits, some 3-wire circuits |

| 3 or more conductors | 40% | Most branch circuits, control wiring |

Diagram illustrating conduit fill percentages for 1, 2, and 3+ conductors based on NEC guidelines.

💡 Key Insight: The 40% fill rule for three or more conductors is most commonly used in electrical installations. This provides adequate space for heat dissipation and wire pulling while maximizing conduit utilization.

Conductor Area Calculation

Every conductor has a specific cross-sectional area including insulation. NEC Chapter 9 Table 5 lists these areas for common conductor types:

Calculation Formula:

Total Area=∑(Area of each conductor)

40% Fill Rule:

Total Conductor Area≤0.40×Conduit Interior Area

NEC Conduit Fill Tables and Charts

Standard Conduit Sizes

Electrical conduit comes in standard trade sizes measured in inches:

Common Trade Sizes: ½", ¾", 1", 1¼", 1½", 2", 2½", 3", 3½", 4", 5", 6"

Maximum Wire Fill Chart - THHN/THWN Conductors

The following chart shows maximum number of THHN/THWN conductors (most common insulation type) at 40% fill:

| Wire Size (AWG) | ½" Conduit | ¾" Conduit | 1" Conduit | 1¼" Conduit | 1½" Conduit | 2" Conduit |

|---|

| 14 AWG | 9 | 16 | 26 | 43 | 58 | 96 |

| 12 AWG | 7 | 12 | 20 | 33 | 44 | 73 |

| 10 AWG | 5 | 9 | 15 | 25 | 34 | 56 |

| 8 AWG | 3 | 5 | 8 | 14 | 19 | 31 |

| 6 AWG | 1 | 4 | 6 | 10 | 14 | 23 |

| 4 AWG | 1 | 2 | 4 | 7 | 10 | 16 |

| 3 AWG | 1 | 1 | 3 | 6 | 8 | 14 |

| 2 AWG | 1 | 1 | 3 | 5 | 7 | 12 |

| 1 AWG | 0 | 1 | 1 | 4 | 5 | 9 |

| 1/0 AWG | 0 | 1 | 1 | 3 | 4 | 7 |

| 2/0 AWG | 0 | 1 | 1 | 2 | 3 | 6 |

| 3/0 AWG | 0 | 0 | 1 | 1 | 3 | 5 |

| 4/0 AWG | 0 | 0 | 1 | 1 | 2 | 4 |

EMT Conduit Internal Areas

Electrical Metallic Tubing (EMT) internal areas for fill calculations:

| Trade Size | Internal Diameter (inches) | 40% Fill Area (sq. in) | Total Area (100%) |

|---|

| ½" | 0.622 | 0.122 | 0.304 |

| ¾" | 0.824 | 0.213 | 0.533 |

| 1" | 1.049 | 0.346 | 0.864 |

| 1¼" | 1.380 | 0.598 | 1.496 |

| 1½" | 1.610 | 0.814 | 2.036 |

| 2" | 2.067 | 1.342 | 3.356 |

| 2½" | 2.731 | 2.343 | 5.858 |

| 3" | 3.356 | 3.538 | 8.846 |

| 3½" | 3.834 | 4.618 | 11.545 |

| 4" | 4.334 | 5.901 | 14.753 |

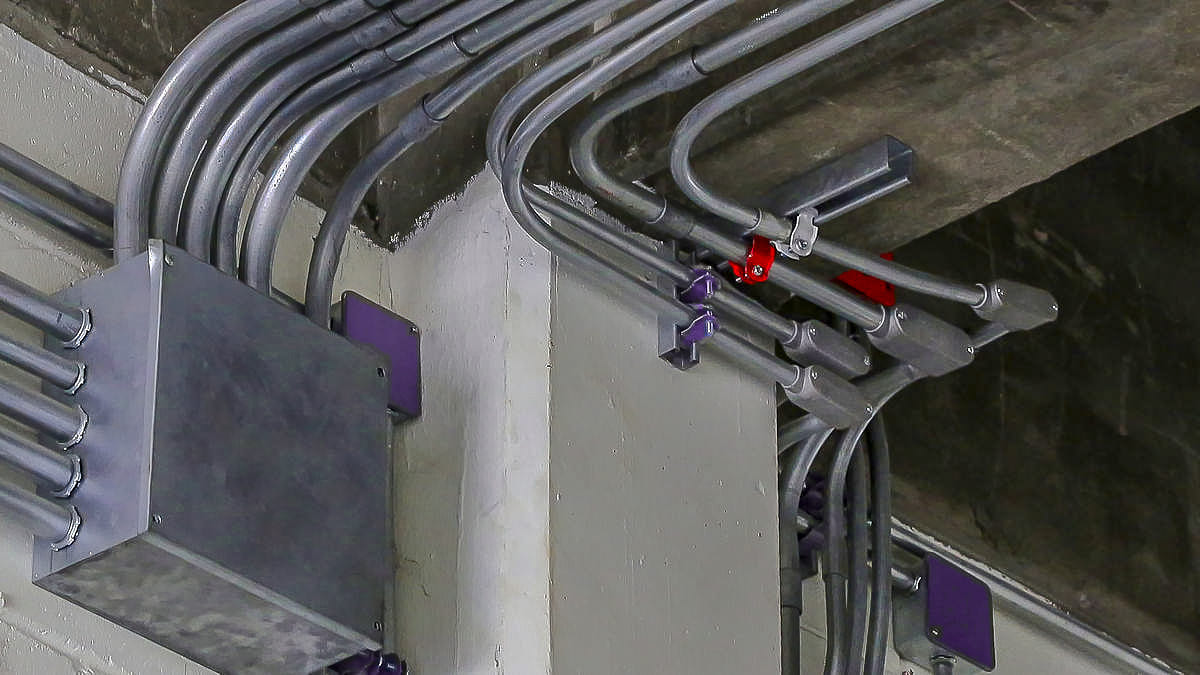

Example of electrical conduit installation showing THHN wires routed through EMT metallic conduits.

Photo by Sen News

Step-by-Step Conduit Fill Calculations

Example 1: Basic Single-Size Conductor Calculation

Scenario: Size conduit for eight 12 AWG THHN conductors

Step 1: Find Conductor Area

From NEC Table 5, 12 AWG THHN = 0.0133 sq. in. per conductor

Step 2: Calculate Total Area

Total Area=8×0.0133=0.1064 sq. in.

Step 3: Determine Required 40% Fill Area

Required conduit area = 0.1064 sq. in.

Step 4: Select Conduit Size

From EMT table, ¾" conduit provides 0.213 sq. in. at 40% fill

0.1064<0.213✓

Answer: ¾" EMT conduit is adequate

Example 2: Mixed Wire Size Calculation

Scenario: Size conduit for the following conductors:

- 4 conductors: 12 AWG THHN

- 3 conductors: 10 AWG THHN

- 1 conductor: 8 AWG THHN ground

Step 1: Find Individual Areas (NEC Table 5)

- 12 AWG THHN: 0.0133 sq. in.

- 10 AWG THHN: 0.0211 sq. in.

- 8 AWG THHN: 0.0366 sq. in.

Step 2: Calculate Total Area

Total=(4×0.0133)+(3×0.0211)+(1×0.0366)

=0.0532+0.0633+0.0366=0.1531 sq. in.

Step 3: Select Conduit

From EMT table, ¾" provides 0.213 sq. in. at 40% fill

0.1531<0.213✓

Answer: ¾" EMT conduit (with 28% margin for future additions)

Example 3: Three-Phase Motor Circuit

Scenario: 480V three-phase motor circuit requiring:

- 3 phase conductors: 6 AWG THHN

- 1 ground conductor: 10 AWG THHN

Step 1: Find Areas

- 6 AWG THHN: 0.0507 sq. in.

- 10 AWG THHN: 0.0211 sq. in.

Step 2: Calculate Total

Total=(3×0.0507)+(1×0.0211)

=0.1521+0.0211=0.1732 sq. in.

Step 3: Select Conduit

¾" EMT provides 0.213 sq. in. at 40% fill

0.1732<0.213✓

Answer: ¾" EMT conduit

Quick Reference Wire Fill Charts

Maximum Conductors for Common Applications

120V Branch Circuits (14 AWG + Ground)

| Conduit Size | 2-Wire + Ground | 3-Wire + Ground | 4-Wire + Ground |

|---|

| ½" | 3 circuits | 2 circuits | 1 circuit |

| ¾" | 5 circuits | 4 circuits | 3 circuits |

| 1" | 8 circuits | 6 circuits | 5 circuits |

240V Circuits (12 AWG + Ground)

| Conduit Size | Single 240V Circuit | Two 240V Circuits | Three 240V Circuits |

|---|

| ½" | ✓ (3 wires) | ✗ | ✗ |

| ¾" | ✓ (3 wires) | ✓ (6 wires) | ✗ |

| 1" | ✓ (3 wires) | ✓ (6 wires) | ✓ (9 wires) |

Derating Considerations

When more than three current-carrying conductors share a conduit, ampacity derating applies per NEC 310.15(C)(1):

| Current-Carrying Conductors | Ampacity Adjustment Factor |

|---|

| 4-6 | 80% |

| 7-9 | 70% |

| 10-20 | 50% |

| 21-30 | 45% |

| 31-40 | 40% |

| 41+ | 35% |

⚠️ Important: Neutral conductors carrying unbalanced current and equipment grounding conductors count as current-carrying conductors for derating purposes. Always verify local code interpretations.

Common Conduit Sizing Applications

Residential Wiring

Typical ½" EMT Applications:

- Single 15A or 20A branch circuit

- Three 14 AWG conductors (2 hot + neutral or 1 hot + neutral + ground)

- Maximum distance: Consider voltage drop for long runs

Typical ¾" EMT Applications:

- Multiple branch circuits to panel

- Service entrance for small loads

- Feeder circuits up to 60A

Commercial Applications

Lighting Circuits:

For commercial buildings with multiple lighting circuits:

- 1" conduit: Up to 8 circuits (14 AWG)

- 1¼" conduit: Up to 13 circuits (14 AWG)

- Consider smart lighting control wiring

Power Distribution:

Office space power distribution typically uses:

- 1" to 1½" conduit for branch circuit homerun

- 2" to 3" conduit for sub-panel feeders

- Larger conduits for main distribution

Industrial Installations

Motor Circuits:

Size based on motor full-load ampacity:

- Include oversized ground wire per NEC 250.122

- Consider VFD installations requiring additional conductors

- Account for control wiring in separate conduits

Control Wiring:

PLC and instrumentation wiring:

- Typically 18-16 AWG

- May require separation from power circuits

- Consider shielded cable requirements

Best Practices and Code Compliance

Installation Best Practices

1. Wire Pulling Limits

- Maximum pull length without junction: 100 feet

- Use pull boxes for longer runs or multiple bends

- Limit total bends to 360° between boxes

2. Conduit Selection

- EMT: Indoor dry locations, easiest to work with

- Rigid PVC: Outdoor underground, corrosion resistance

- Rigid Metal: High-abuse areas, mechanical protection

- Flexible: Short connections to equipment

3. Future Expansion

Consider oversizing conduit by one size for:

- Potential circuit additions

- Equipment upgrades

- Easier wire pulling

- Rule of thumb: Design for 60-70% fill rather than maximum 40%

Common Mistakes to Avoid

1. Forgetting Ground Conductors

Always include equipment grounding conductors in fill calculations. This is a frequent oversight that causes code violations.

2. Mixing Conductor Types

Use consistent insulation types (all THHN or all THWN-2). Mixing types complicates calculations and may violate temperature ratings.

3. Ignoring Ambient Temperature

High-temperature locations require:

- Temperature rating adjustments

- Possible larger conduit for heat dissipation

- Special insulation types

4. Undersizing for Long Runs

Account for:

- Voltage drop on long runs

- Difficulty pulling wire through small conduit

- Future troubleshooting and maintenance

Inspection and Compliance

Before Installation:

- Verify local amendments to NEC

- Obtain required permits

- Submit drawings for approval

- Confirm conduit type specifications

During Installation:

- Mark conduit contents at panels and boxes

- Document as-built conditions

- Use proper conduit supports per NEC Table 344.30(B)(2)

- Maintain minimum bending radius

After Installation:

- Test for shorts and grounds

- Verify proper grounding continuity

- Label circuits clearly

- Document in panel schedules

Conduit Fill Calculator Guide

Manual Calculation Steps

- Step 1: List all conductors including grounds

- Step 2: Find each conductor area from NEC Table 5

- Step 3: Sum total conductor area

- Step 4: Select conduit with 40% fill area ≥ total conductor area

- Step 5: Verify with NEC Annex C tables

Online Calculator Use

When using online conduit fill calculators:

- Select conduit type (EMT, PVC, Rigid)

- Enter conductor count by size

- Specify insulation type (THHN/THWN most common)

- Review recommended size and fill percentage

- Always verify critical calculations manually

Quick Sizing Rules of Thumb

For THHN/THWN Copper:

- ½" conduit: Up to 9 conductors of 14 AWG

- ¾" conduit: Up to 12 conductors of 12 AWG

- 1" conduit: Up to 15 conductors of 10 AWG

- Add one size: If near maximum or long pull

Advanced Considerations

Special Conductor Types

- Compact Conductors: Smaller cross-section, allow more per conduit

- High-Temperature Conductors: THHN vs THWN-2 ratings

- Armored Cable: Cannot mix with individual conductors in conduit

- Control Cable: Different fill rules for instrumentation

Underground Installations

PVC conduit for direct burial requires:

- Minimum burial depth per NEC 300.5

- Proper bedding and backfill

- Warning tape placement

- Larger size for thermal considerations

Parallel Conductors

For large loads requiring parallel conductors:

- Equal lengths for current sharing

- Same conduit size for each set

- Separate grounding per NEC 250.122

- Phase identification marking

Conclusion: Ensuring Safe and Compliant Conduit Installation

Proper conduit fill is fundamental to electrical safety, code compliance, and installation efficiency. By following NEC guidelines, using accurate calculations, and applying the charts and formulas in this guide, you can size conduits correctly for any application while maintaining code compliance and installation quality.

Key Takeaways:

- Always use the 40% fill rule for three or more conductors

- Include all conductors (power and ground) in calculations

- Select next size up when near maximum fill

- Consider future expansion in your design

- Verify calculations with NEC tables and local codes

Whether sizing conduit for simple residential circuits or complex industrial installations, the principles remain consistent. Proper planning, accurate calculations, and adherence to NEC requirements ensure safe, reliable, and code-compliant electrical systems.

For related electrical calculations and design guidance, explore our comprehensive resources on wire sizing, circuit breaker selection, and electrical safety practices.

🔗 Related Posts

Helpful Calculators

Credits